AUMA Actuators Limited

AUMA Actuators Secures Framework with Southern Water

AUMA Actuators secures framework with Southern Water

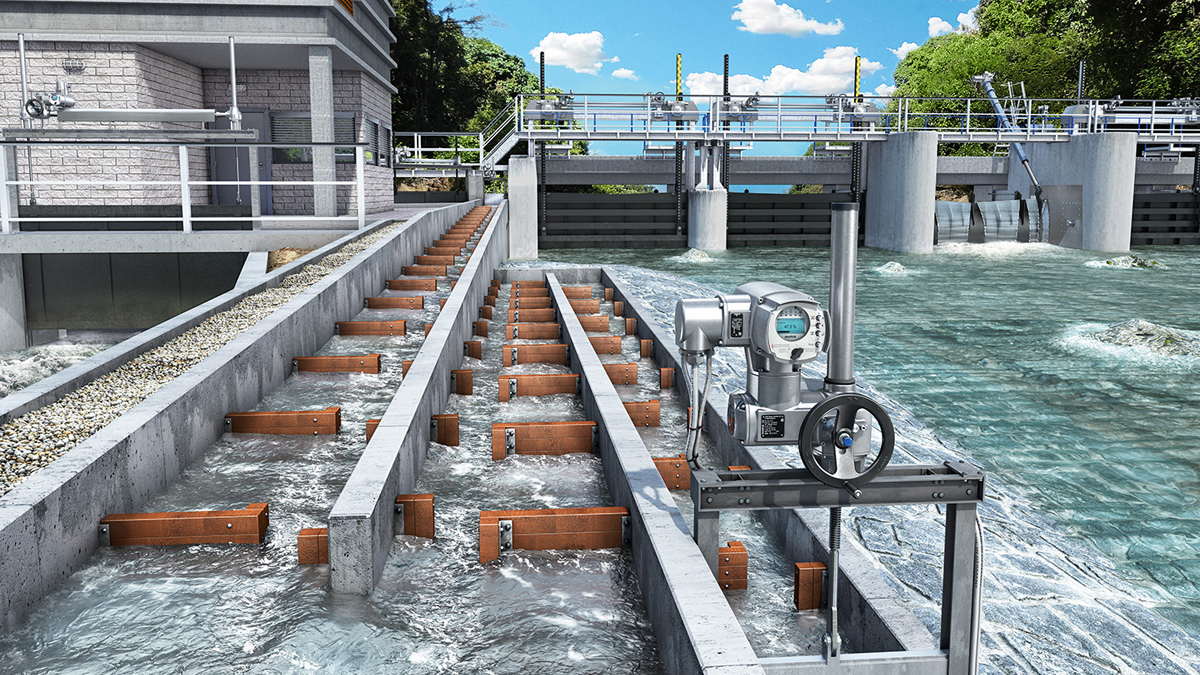

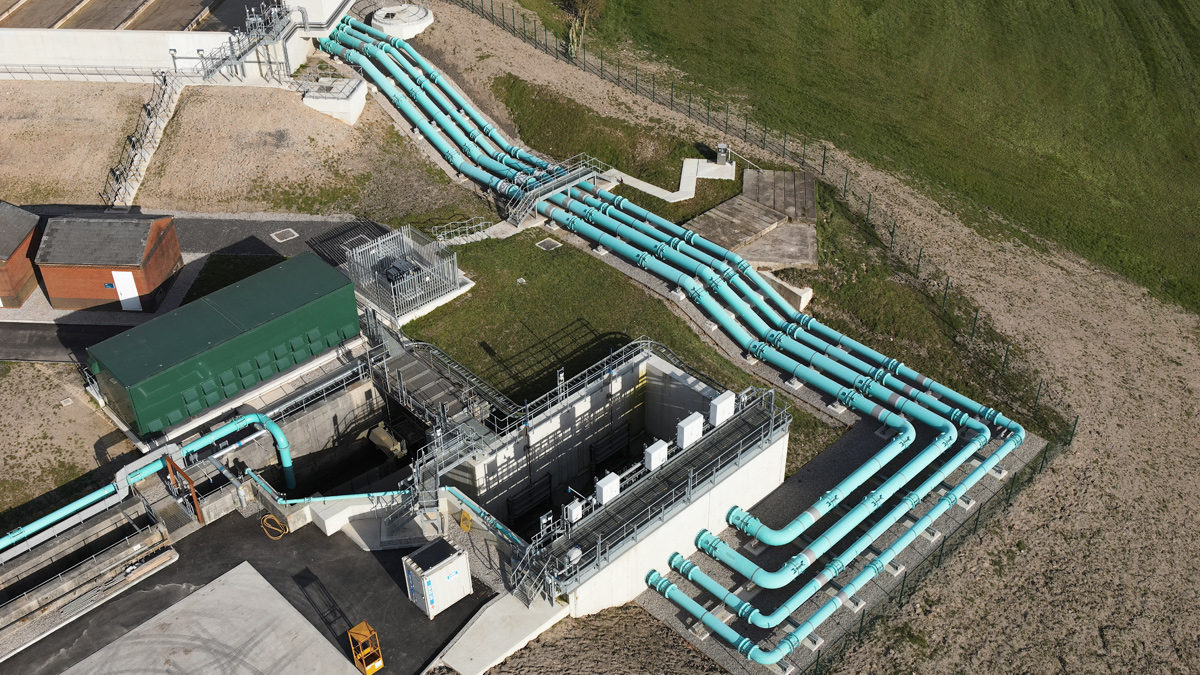

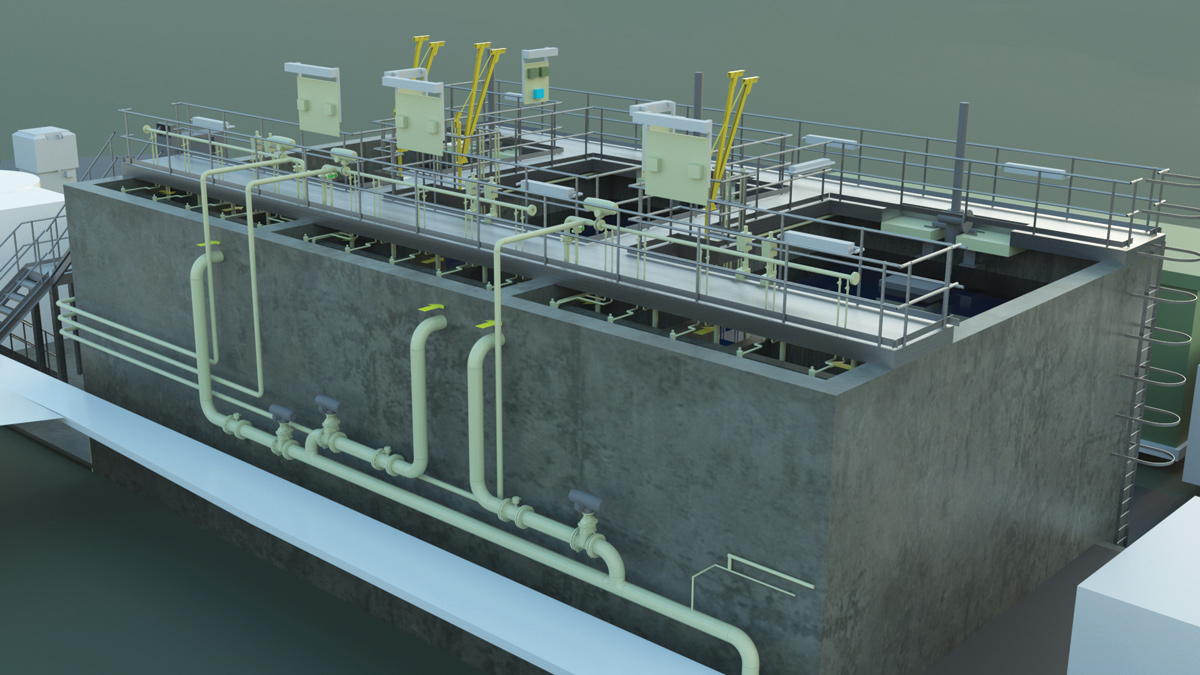

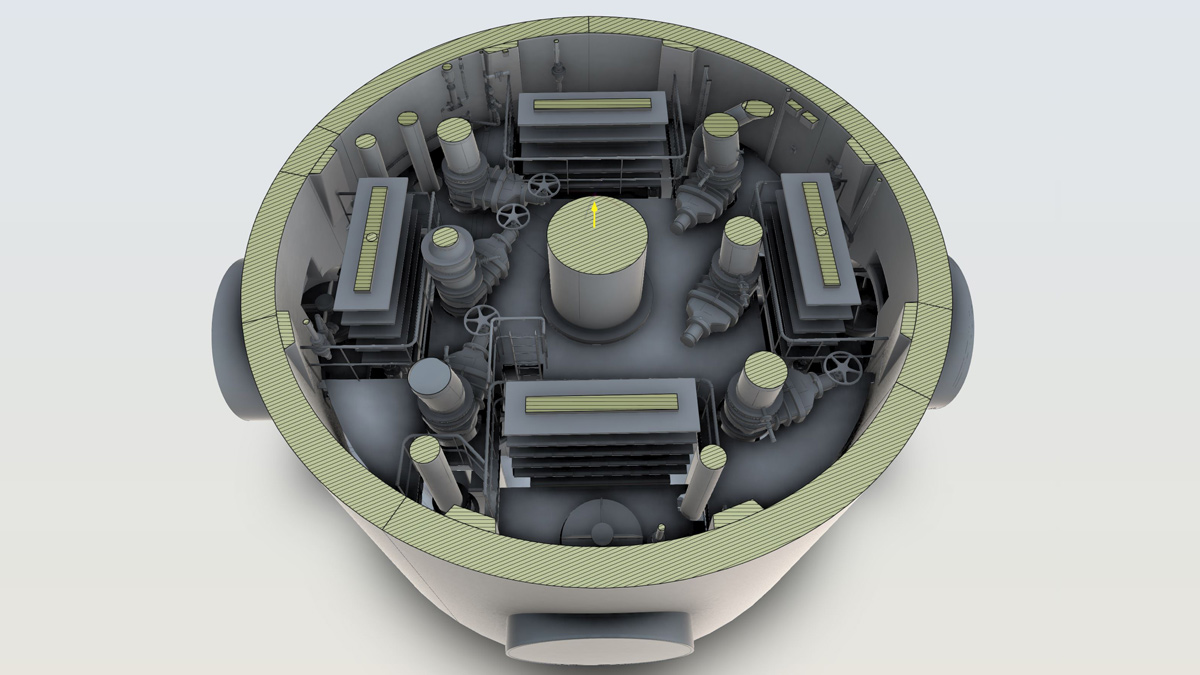

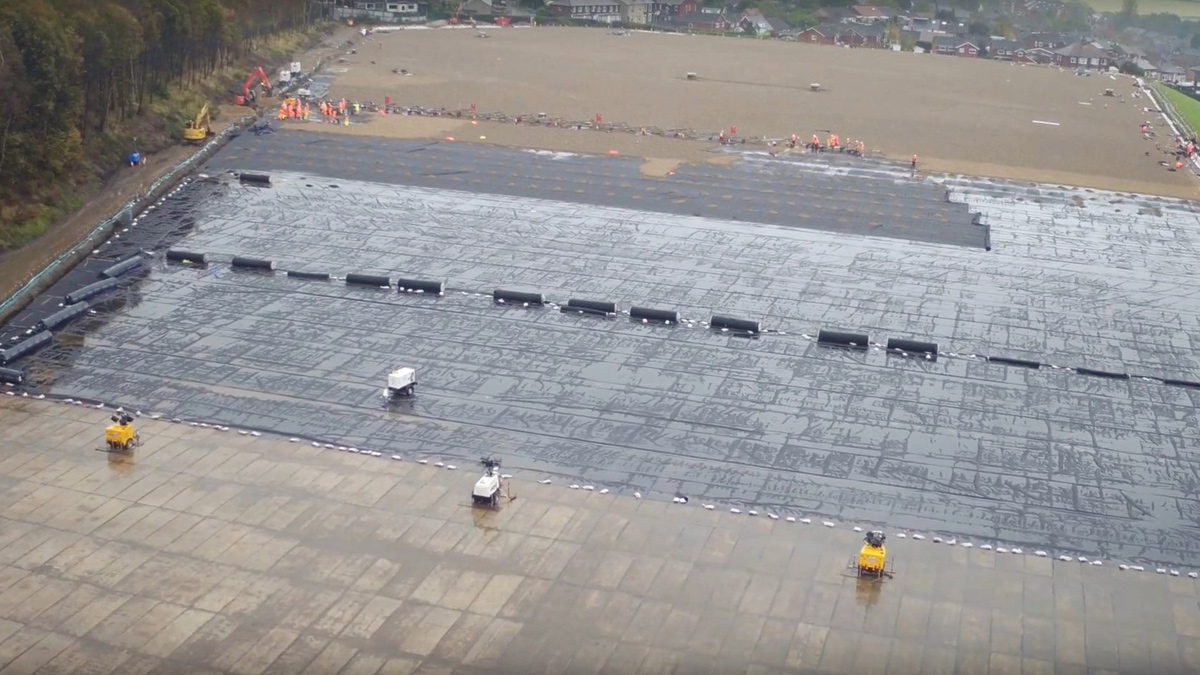

Southern Water (SW) provides essential water services to 2.5 million customers and wastewater services to more than 4.7 million customers across Sussex, Kent, Hampshire and the Isle of Wight. The new framework agreement will see AUMA deploy its new and unique process to service, maintain and replace a range of actuators across the entire SW region, which covers almost 4,450km2.

MIchael Upcraft is Southern Water’s Framework Manager. He said:

“With a 13,929 kilometre network of pipes and 205 service reservoirs, we deliver a continuous supply of clean water to our customers. Our 39,808 kilometres of sewers and 3,321 pumping stations collect wastewater from our customers’ homes and businesses and from outside drains.

“AUMA’s capacity to source and supply its comprehensive range of high quality, high performance electric actuators and critical spare parts from within the EU is a major benefit to us. It means we are able to respond quickly, serving people and businesses throughout our supply region.”

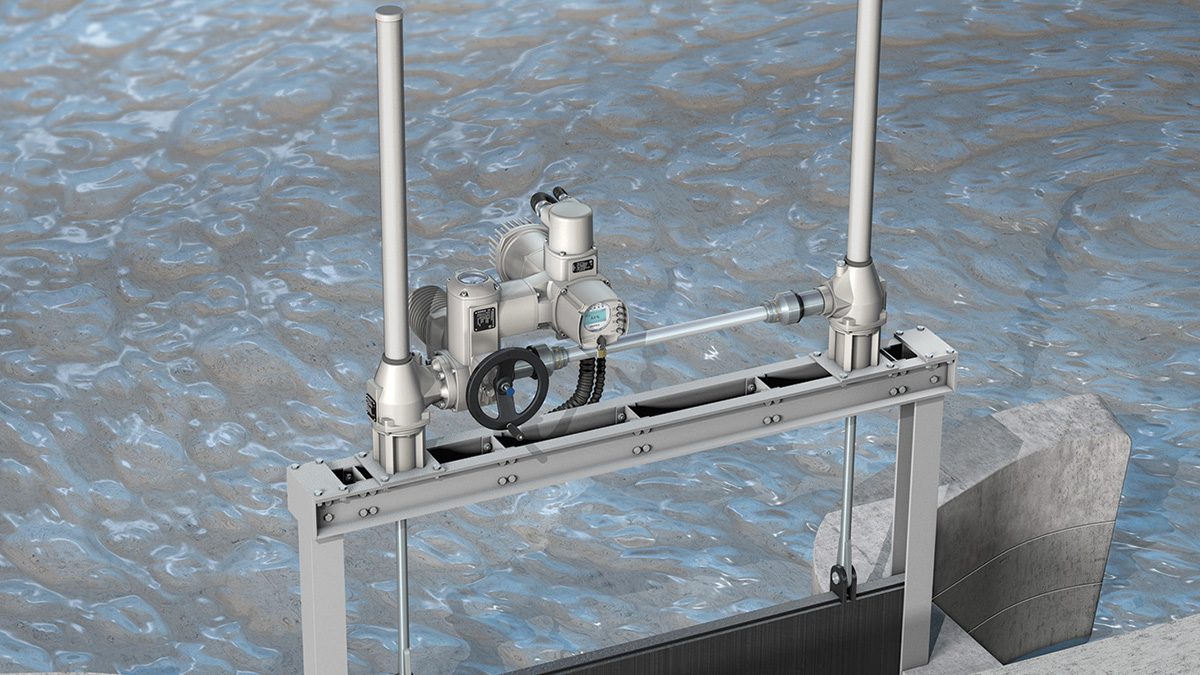

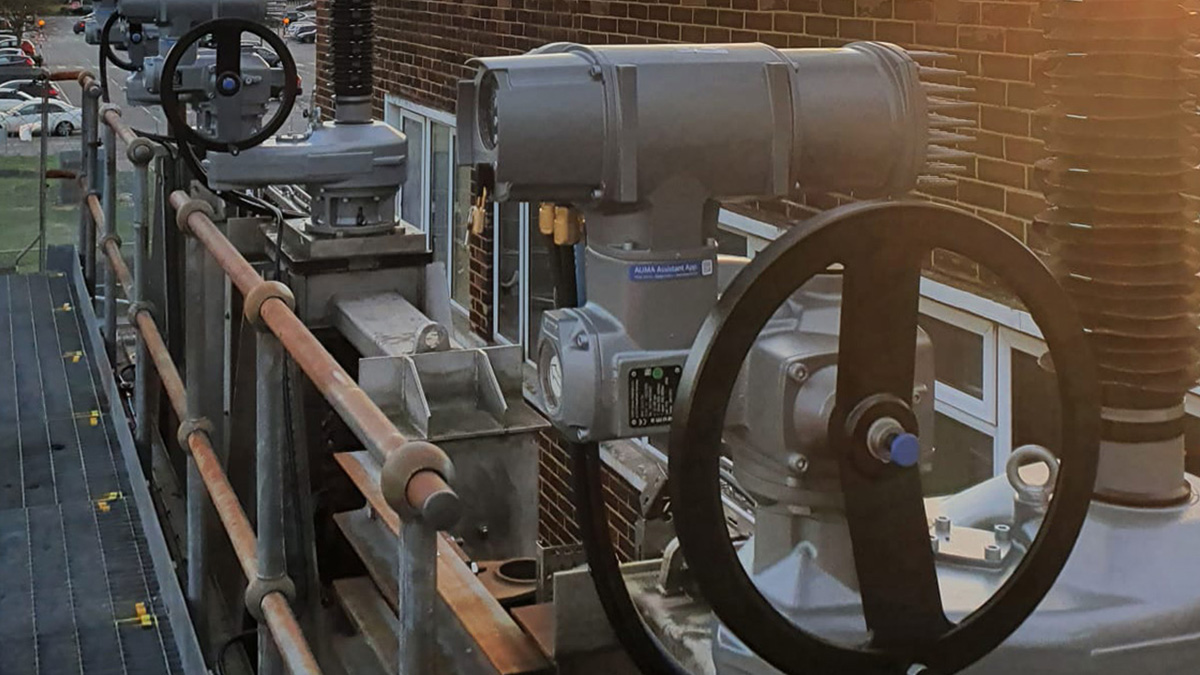

As part of the new framework agreement, SW now has access to AUMA’s unique ‘rapid response’ service to replace both AUMA and other manufacturers’ equipment, as well as a ‘replacement in advance’ for critical actuators.

Paul Hopkins is AUMA UK’s Managing Director. He says:

“Southern Water constantly monitors its water and wastewater sites and networks, conducting maintenance and developing new infrastructure where necessary. We have built a close and positive relationship with the company, which has resulted in securing our framework with this important water utility.

“The water company plays a critical role that goes beyond providing an essential public service. It aims to help tackle the climate emergency, support the communities it serves and contribute to the growth of the south west’s regional economy. It is great to be part of that journey.”

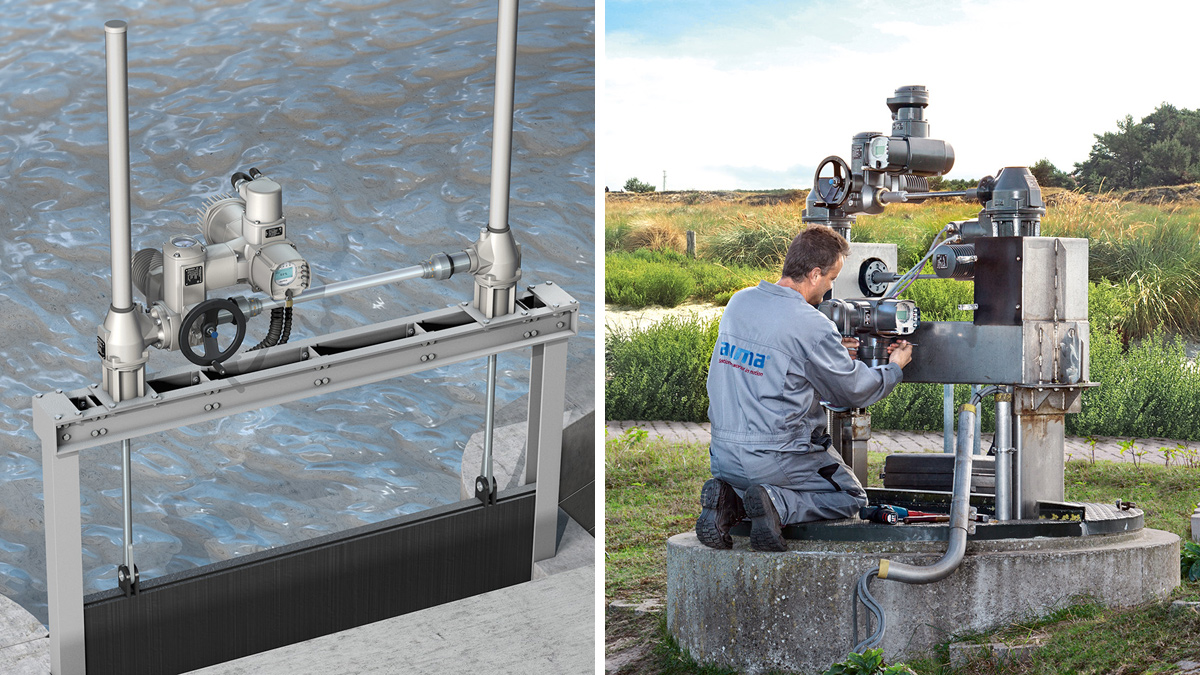

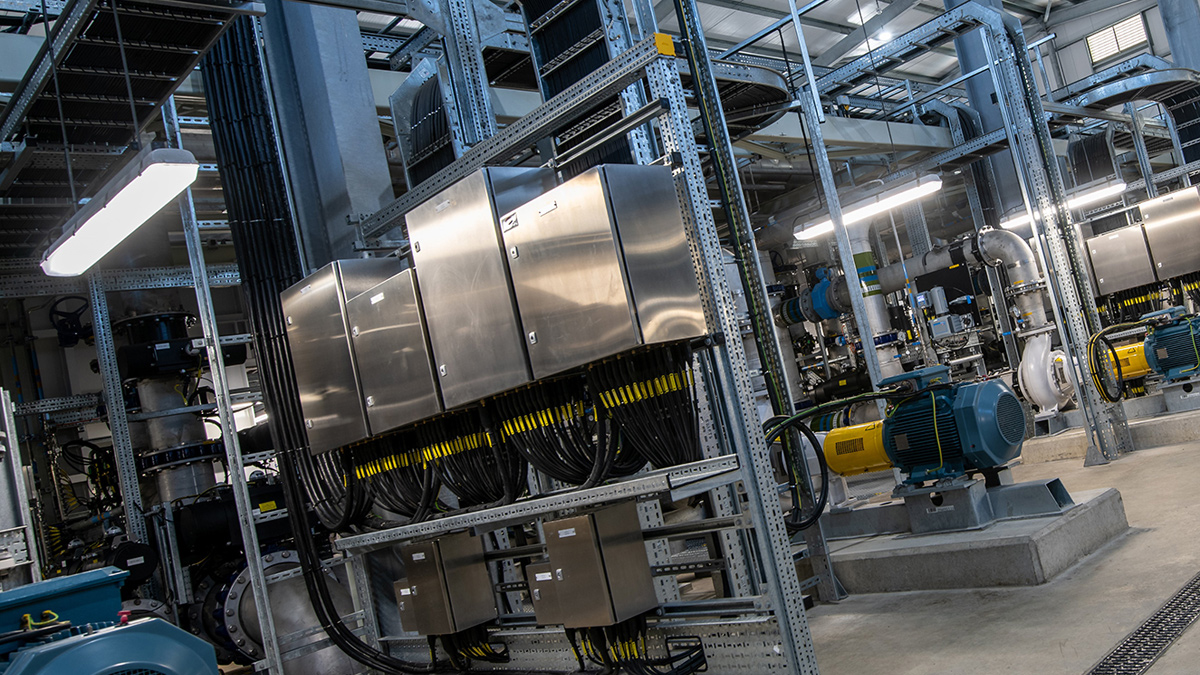

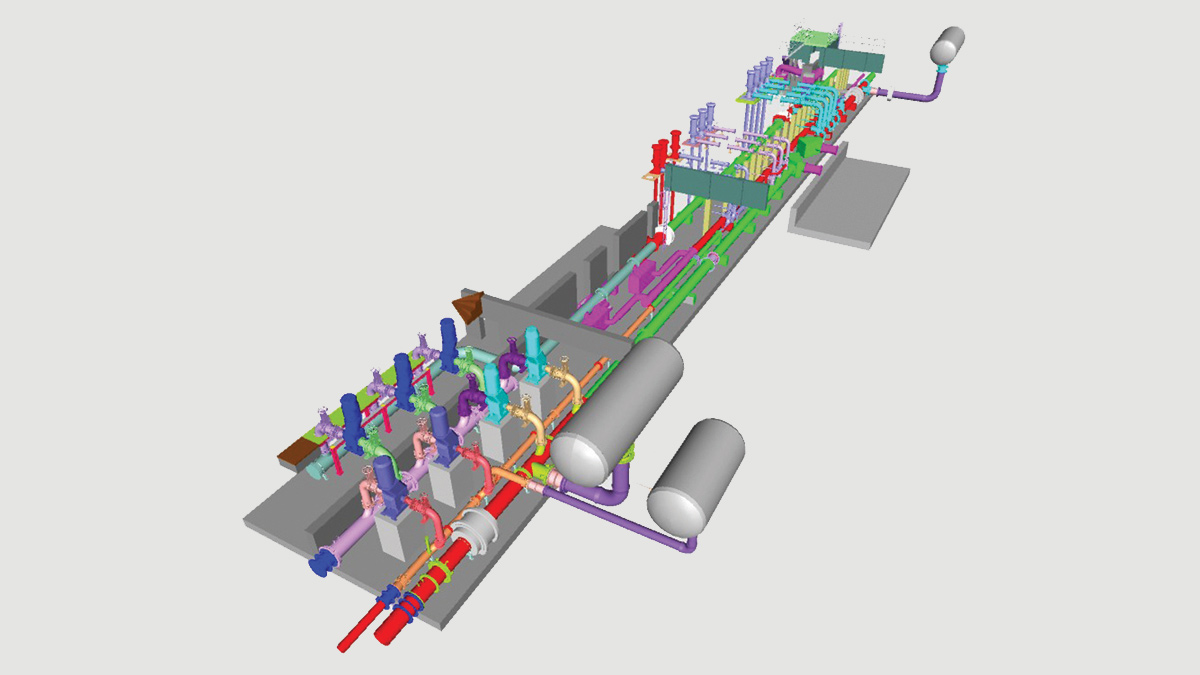

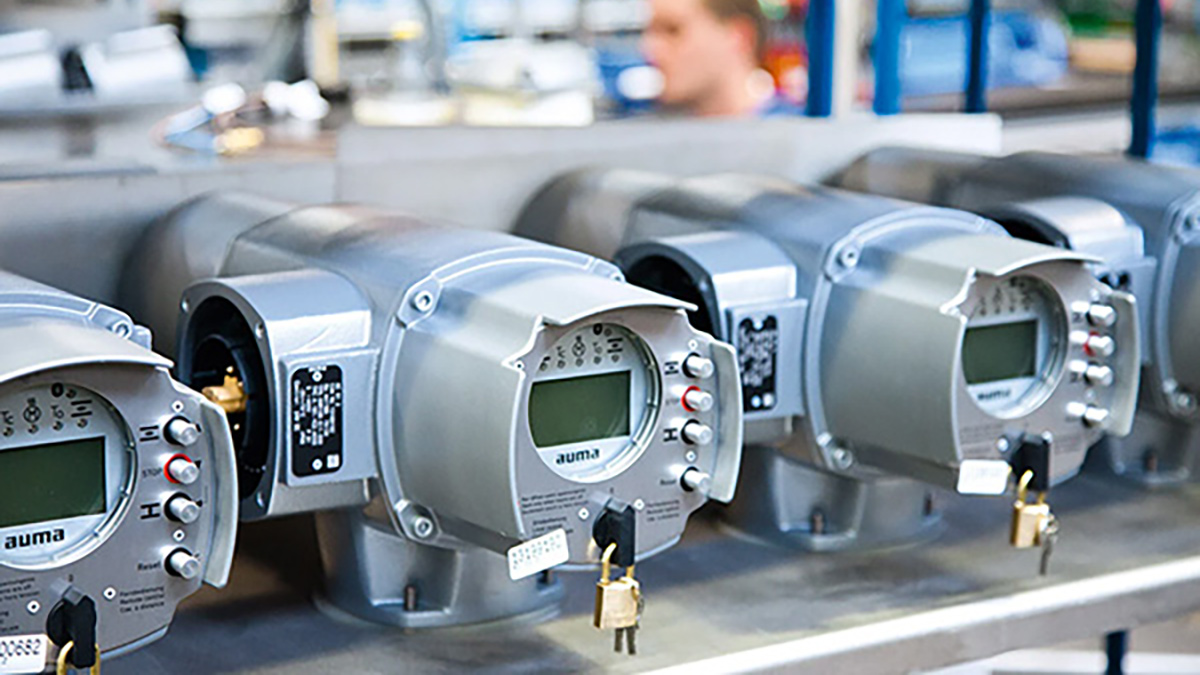

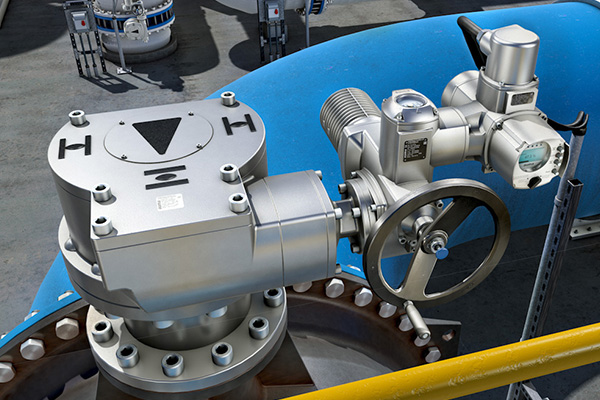

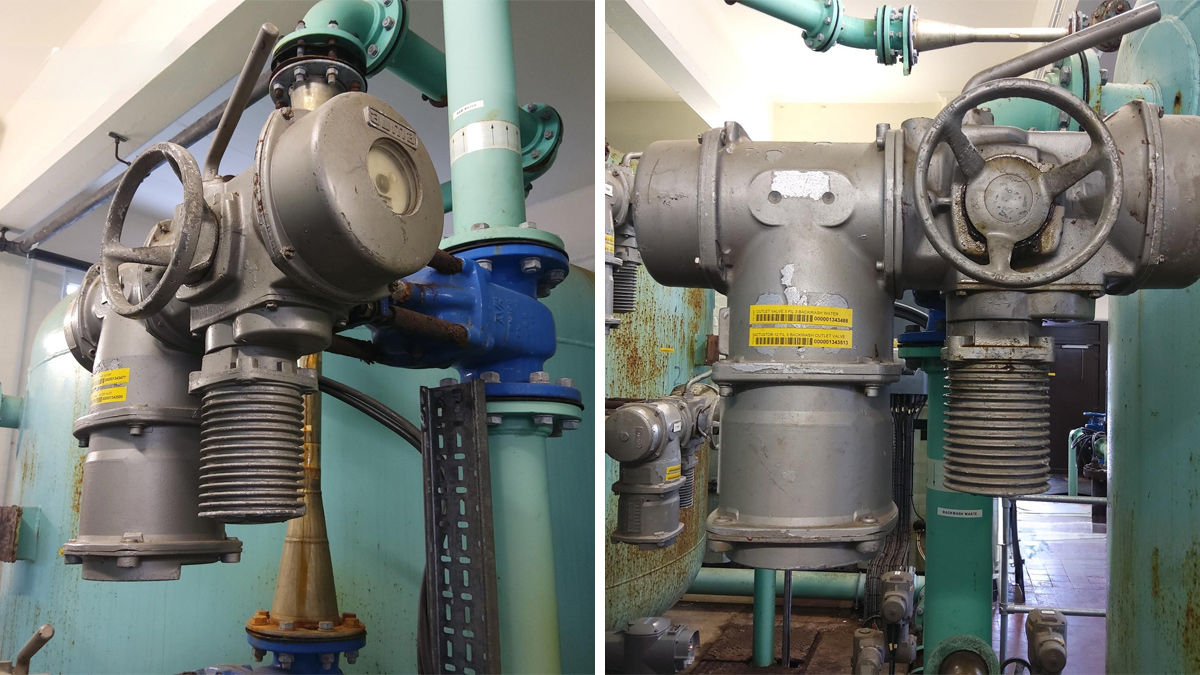

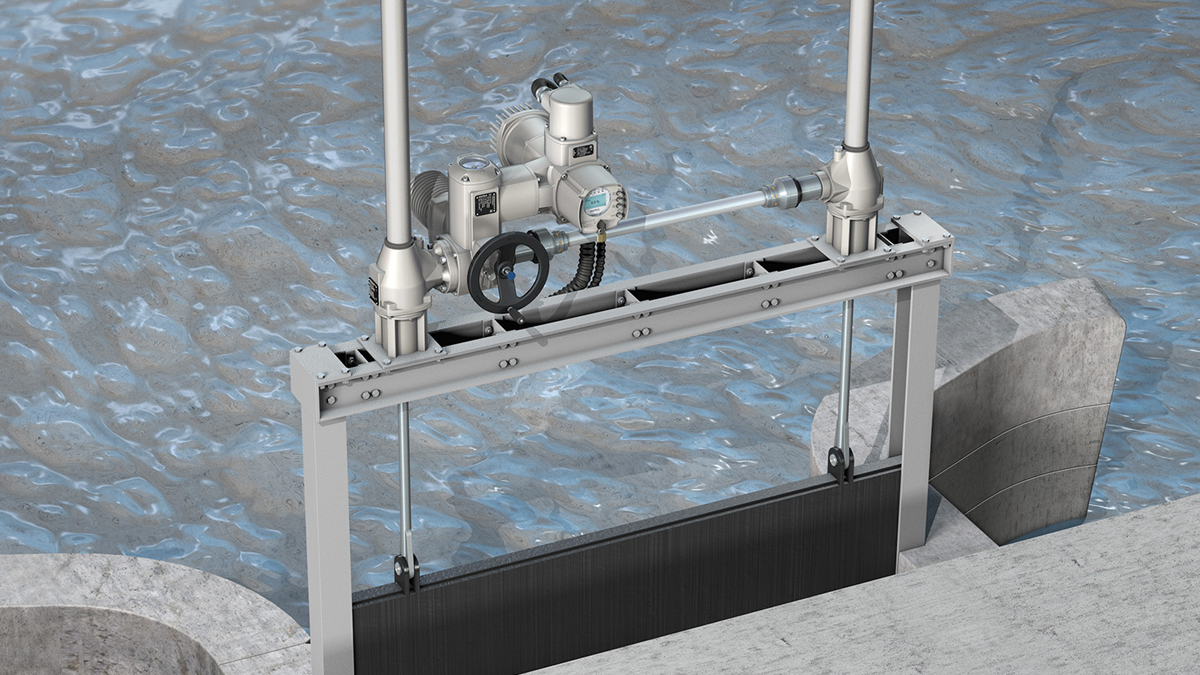

SW aims to maximise the availability of actuated valve operations throughout its region. The size and operating parameters of each installation varies, with a wide combination of actuators, controls and drive couplings required to be available at short notice. AUMA’s extensive range of high performance actuators is designed using a modular approach to actuator components. Actuators can be quickly combined to provide a bespoke actuator assembly constructed to the exact requirements of applications.

AUMA is creating a unique online Southern Water Knowledge Base, which will be accessible to all registered SW engineers and technicians. This will provide 24/7/365 access to essential information, video tutorials and technical information. In addition, AUMA has introduced a number of innovations – from reducing its environmental impact through the use of sustainable packaging, to improving health and safety by reducing time on site undertaking repairs.

AUMA is also providing full training to SW maintenance staff via its AUMA Certified Engineering (ACE) training. Delivered on-site, on-line or in AUMA’s dedicated training suite at its head office in Clevedon, Somerset, ACE is a structured programme that trains technicians to install, operate, maintain and troubleshoot AUMA’s actuators, meeting asset management obligations to maintain equipment in line with the manufacturer’s recommendations. Accredited ACE Technicians are provided with ID cards to prove their level of competency.

For more information contact AUMA Actuators Ltd | +44 (0) 1275 871141 | www.auma.co.uk

About AUMA Actuators Limited

Based in Clevedon, near Bristol, AUMA is the UK subsidiary of the global AUMA Reister GmbH and Co., the world’s largest manufacturer of electric valve actuators, operating on every continent, with 2,300 employees in 30 locations.

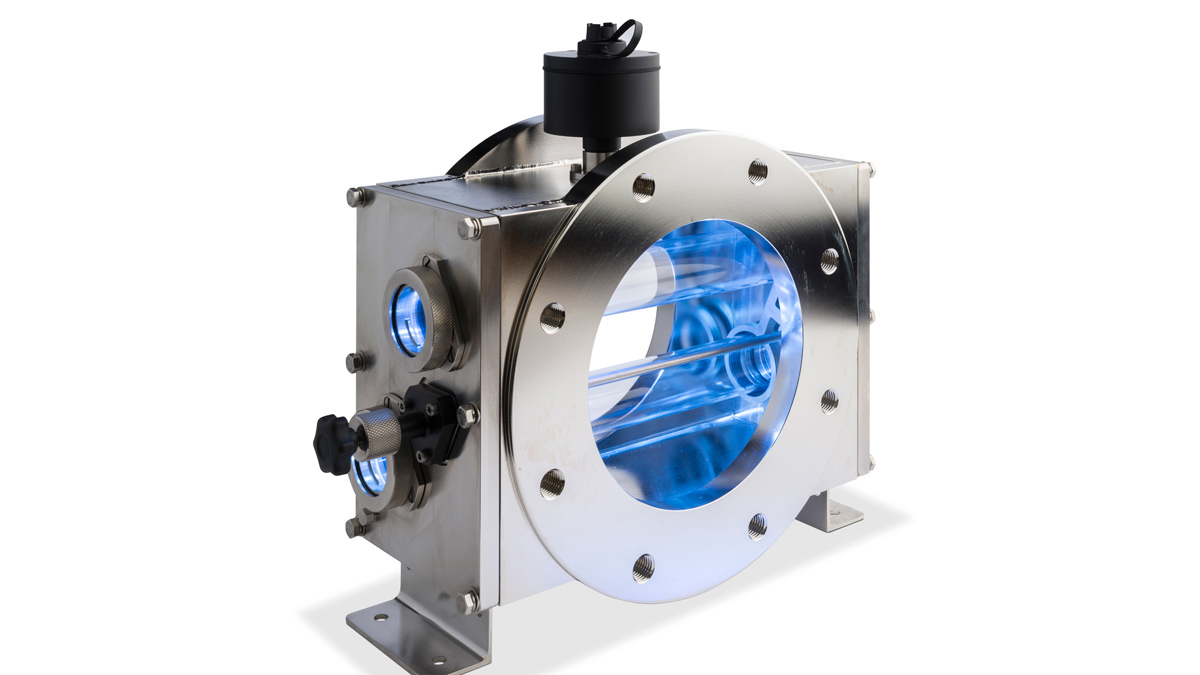

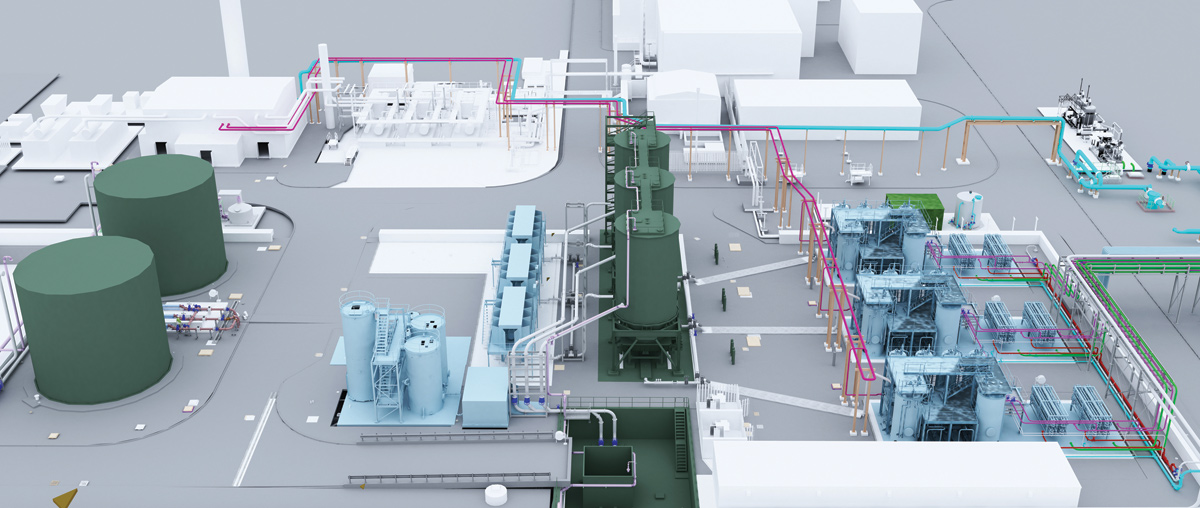

AUMA is the world leader in modular electric valve actuators and gearboxes, supplying a full range of actuators right across the process, water, petrochemical and energy sectors. AUMA manufactures robust, reliable equipment with sophisticated control and connectivity options, backed up with exceptional service support.

AUMA benefits include:

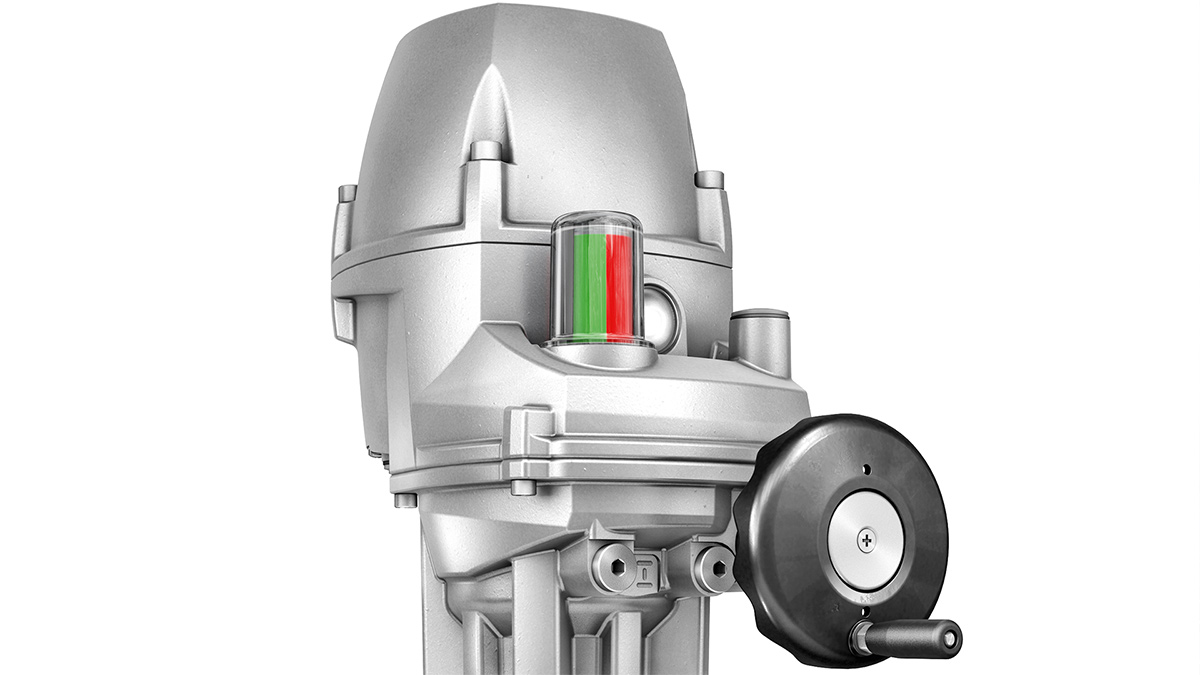

- Rugged and reliable products.

- Double-sealed actuator housing to protect the electronics.

- Tough and resilient finish.

- Powerful, with multi-turn actuators from 7 to 59,000 ft lb (10 to 80,000 Nm) and thrust acceptance up to 900,000 lbs (4,000 kN) and part-turn actuators from 18 to 498,000 ft lb (25 to 675,000 Nm).

- Worldwide availability and support.

- Modular, user-friendly design which provides key benefits such as:

- Supply subcontractors with the appropriate components to allow-pre-assembly

- Reduce time on site – plug and play

- Mount gearboxes up to 100m from the actuator controls to aid access and minimise health and safety risks

ACE Technician Scheme

ACE Technicians can be in-house or part of your service organisation. The ACE (AUMA Certified Engineering) programme has three levels, allowing operatives to be certified for installation or for advanced configuration, troubleshooting and repair. The ACE scheme means that you can have trained, card-carrying AUMA ACE Technicians as part of your own organisation or as part of your service partner’s staff, working in partnership with the service offered by AUMA UK’s head office in Bristol.