AUMA Actuators Limited

AUMA Expands its Retrofit Services for Actuators

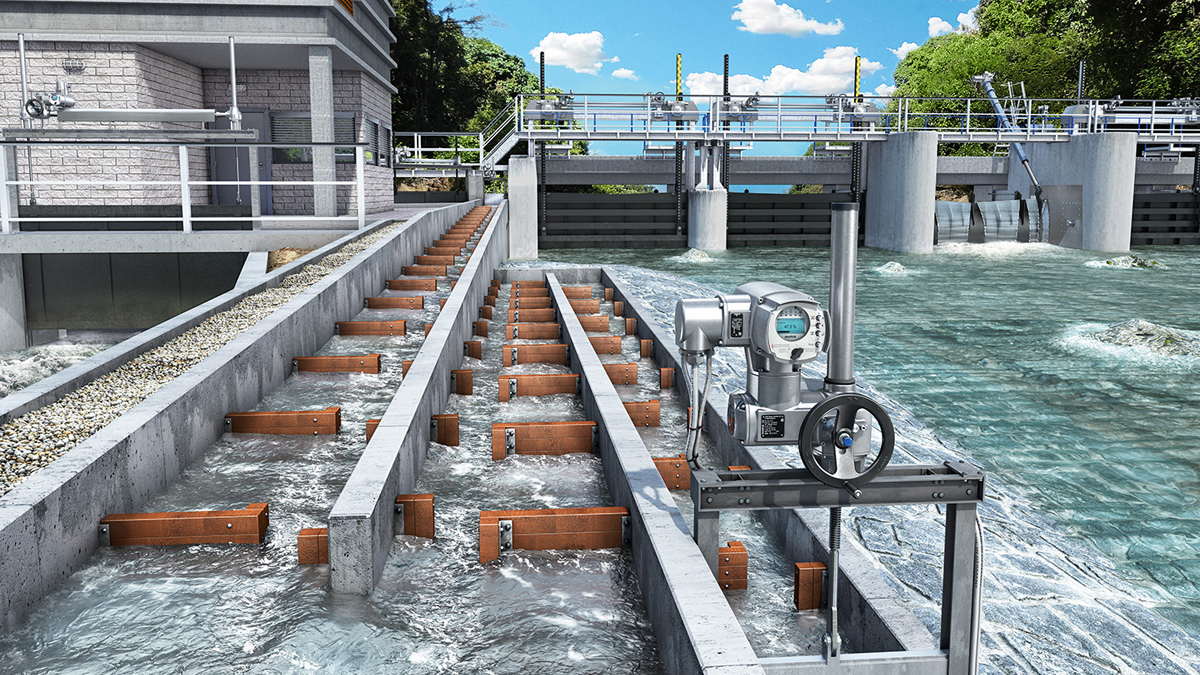

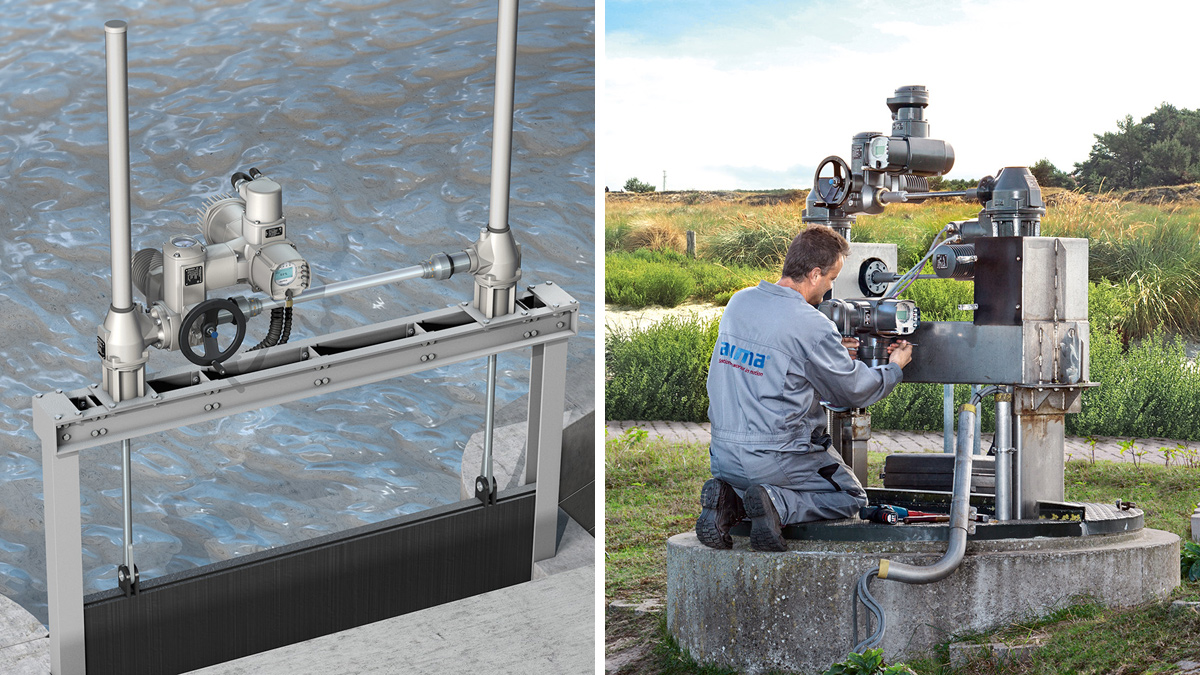

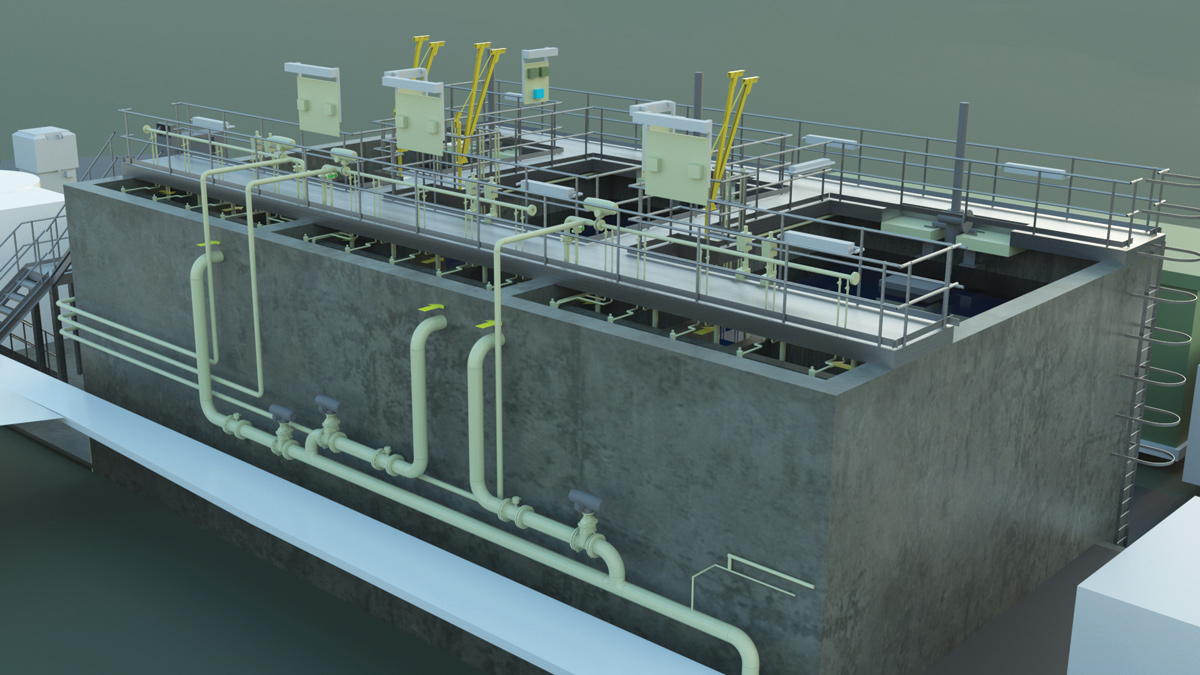

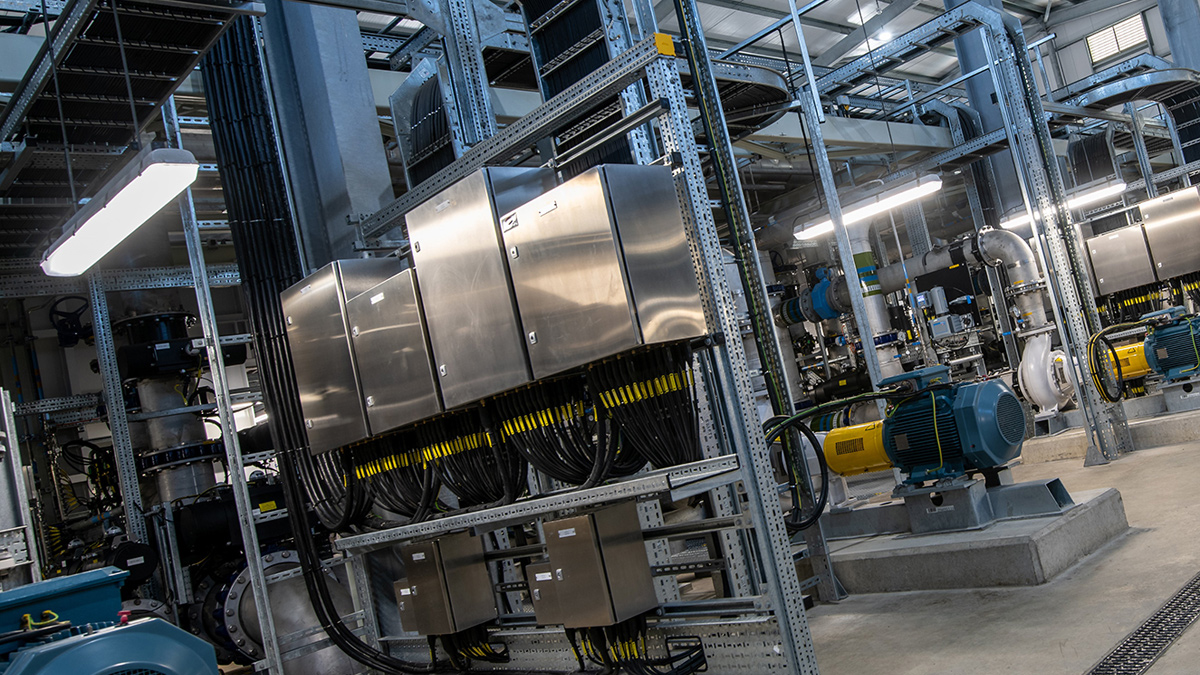

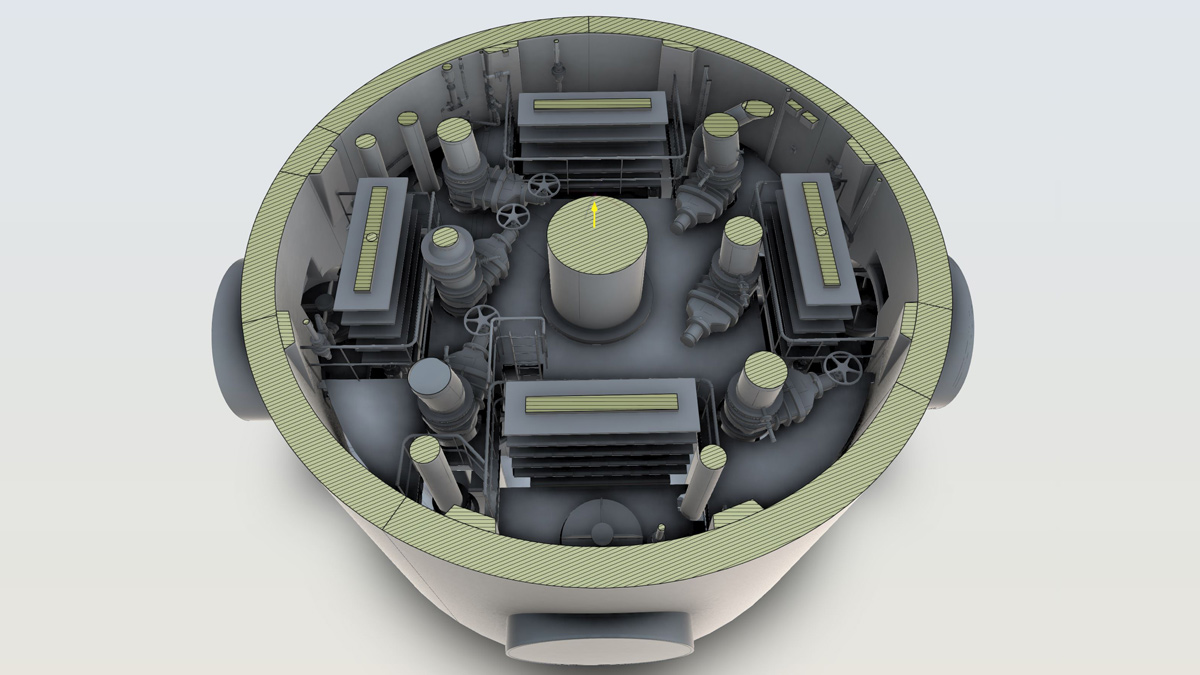

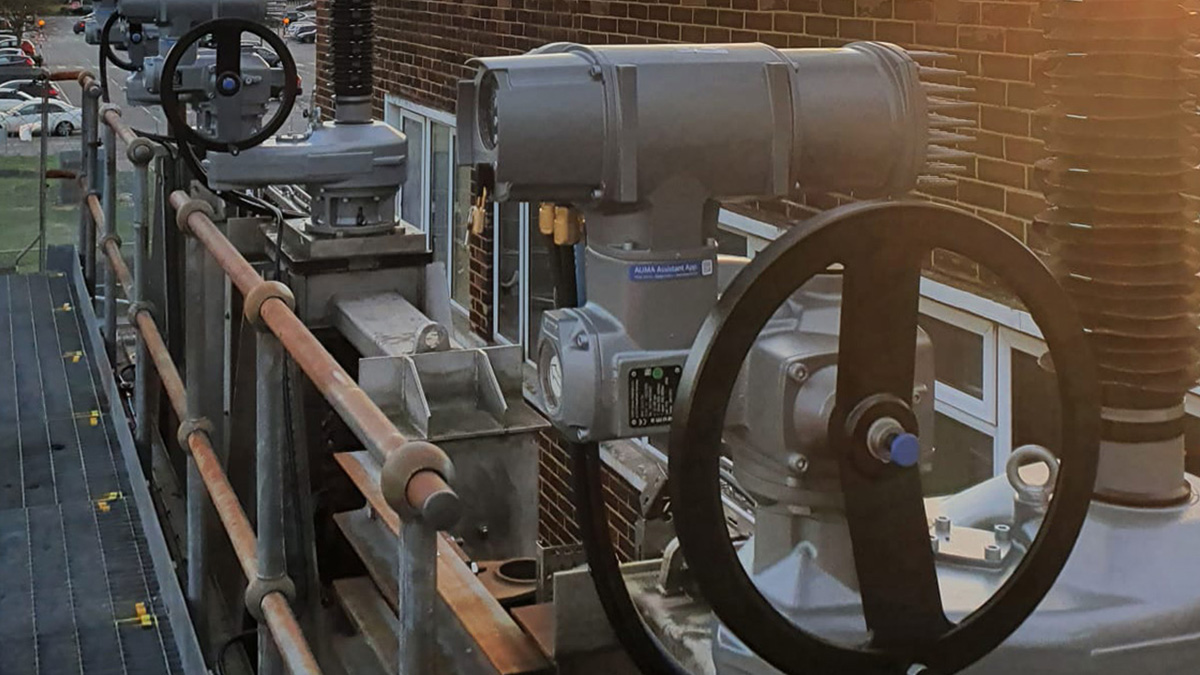

The AUMA Retrofit Service helps plant operators upgrade their existing plants with modern, high-performance valve actuation technology

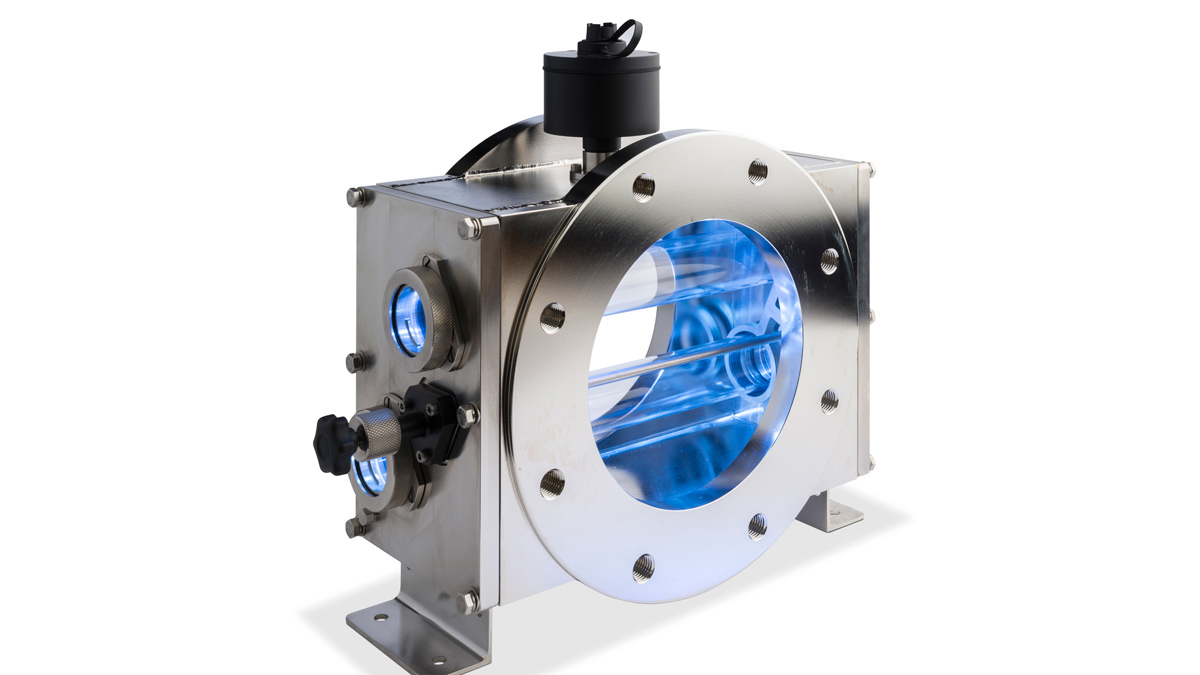

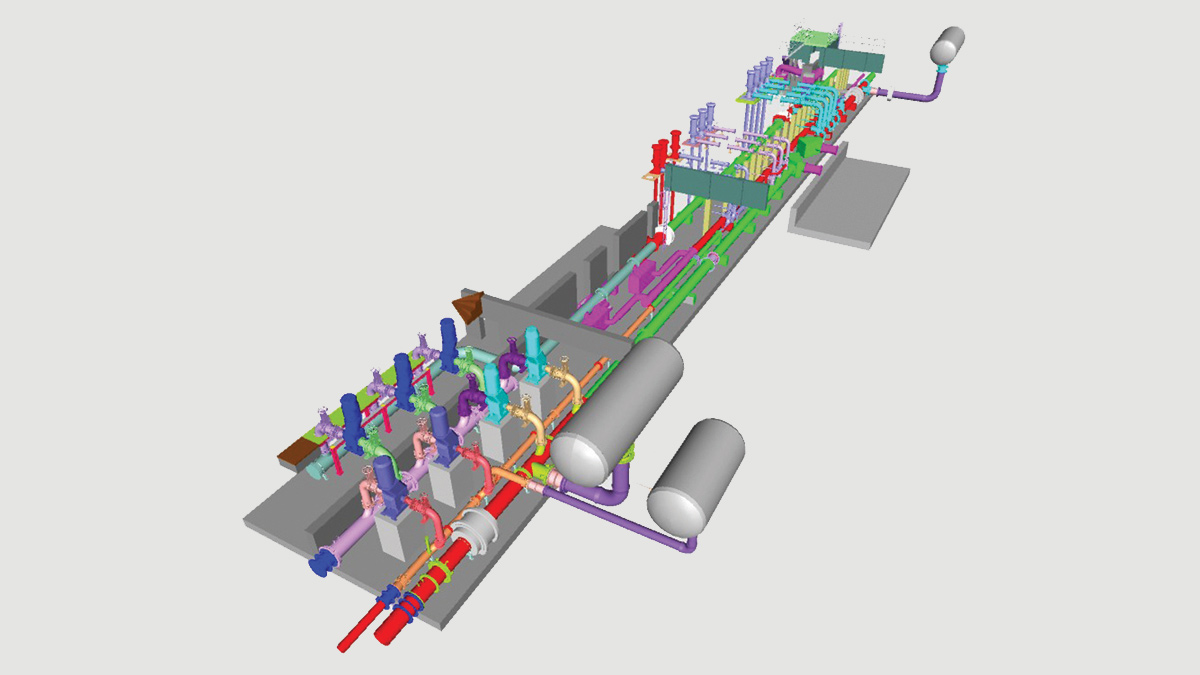

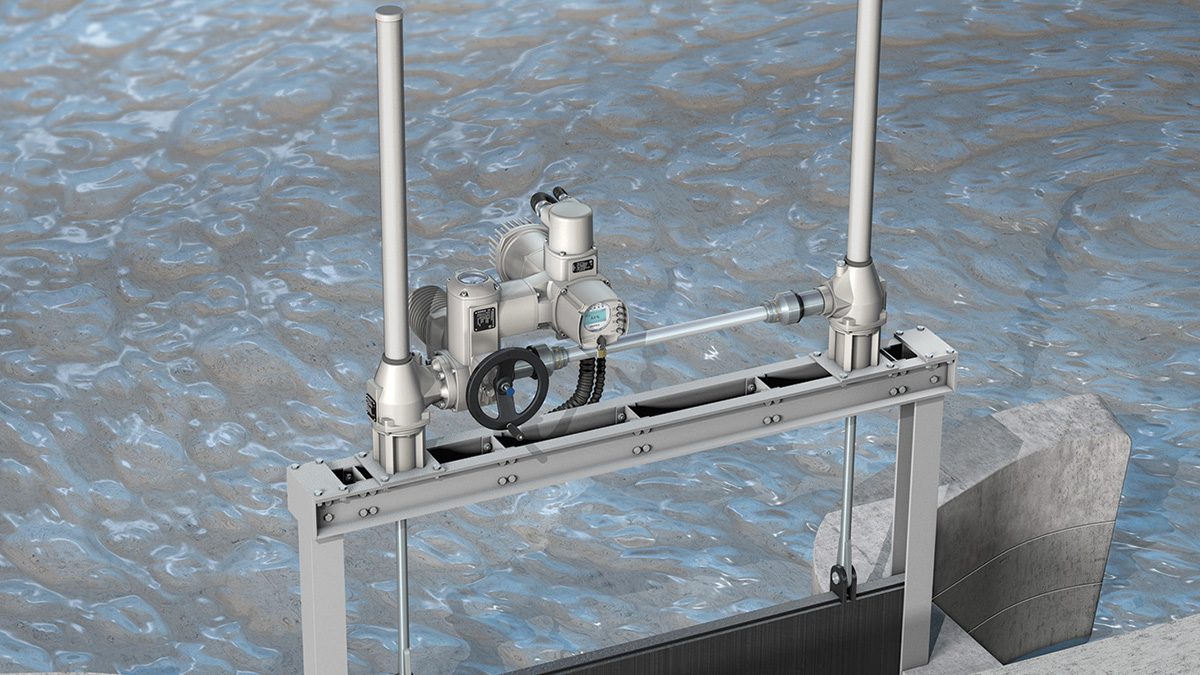

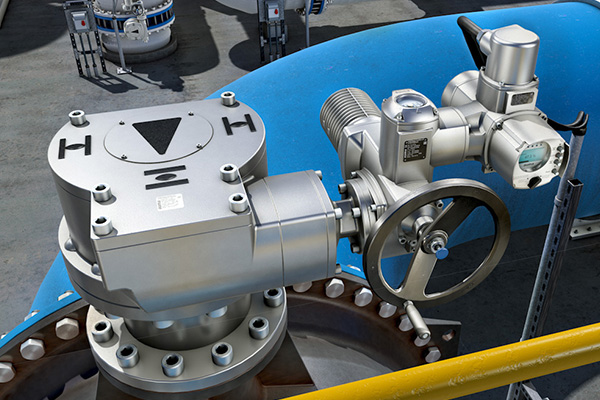

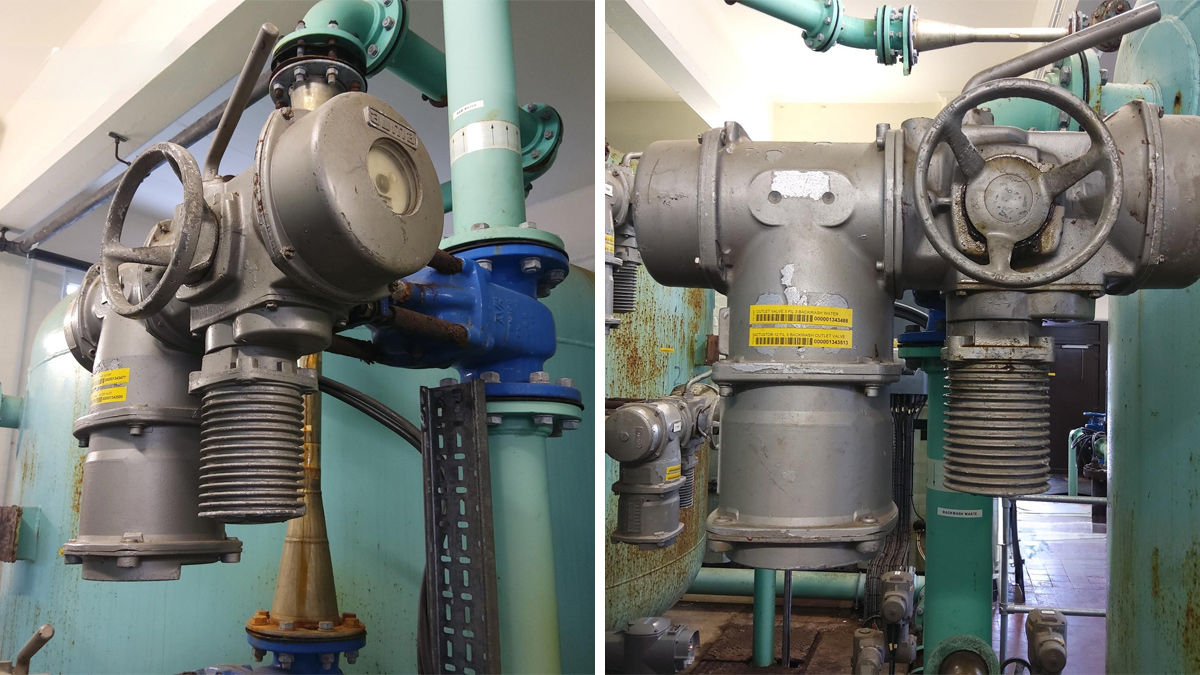

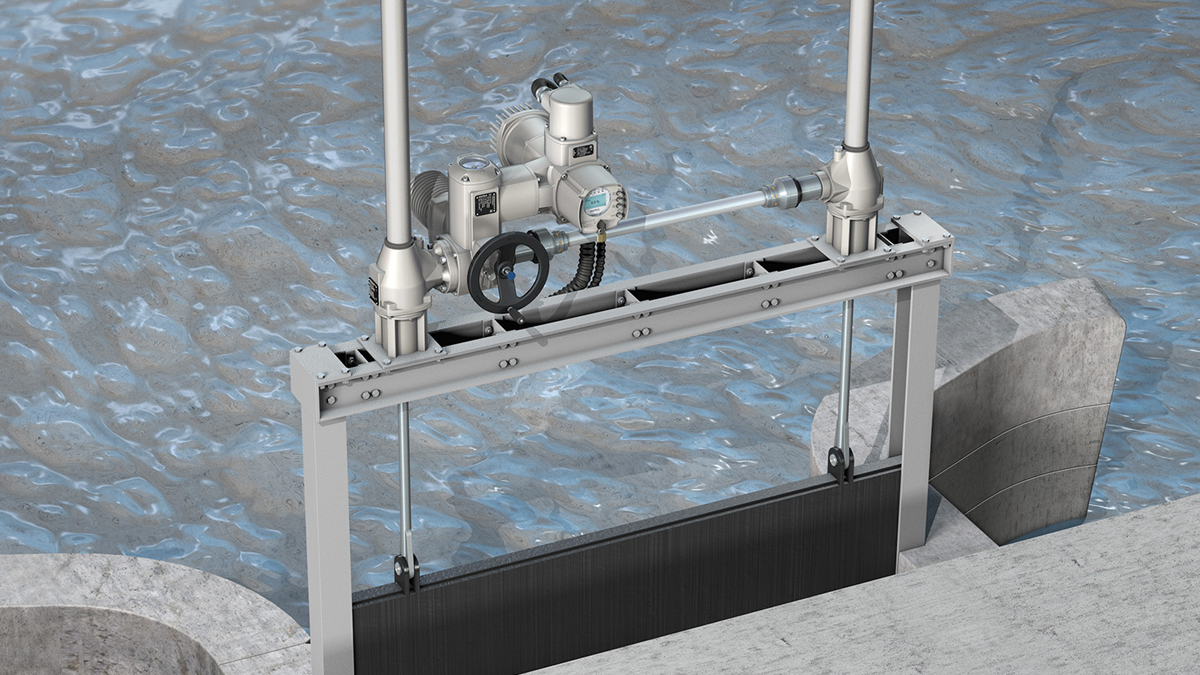

Today, changing requirements and increasing digitalisation mean that many plant operators need smart electric actuators that provide high levels of connectivity to ensure efficient and reliable valve automation.

So what should they do when a new control system is introduced, or new requirements for diagnostics are beyond the capability of the existing actuators? Is it sufficient just to retrofit new communication interfaces to the existing actuators, or would it be better to replace the entire actuators? How to proceed with manually operated valves that need to be automated?

As part of the AUMA Retrofit Service, experienced AUMA experts provide comprehensive advice on all these questions, working closely with the client to develop a custom plan to modernise the plant’s valve automation technology. AUMA takes care of the entire project management: from a detailed analysis of the requirements, through the selection and sizing of suitable actuators, to installation and commissioning by qualified AUMA service technicians.

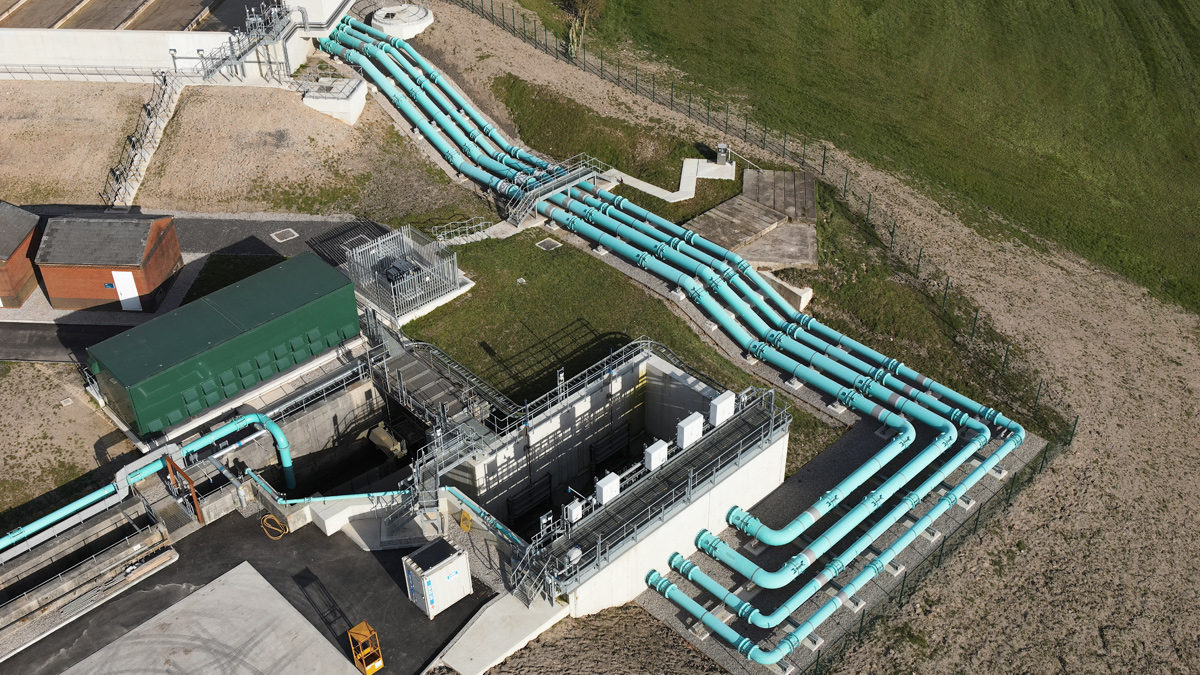

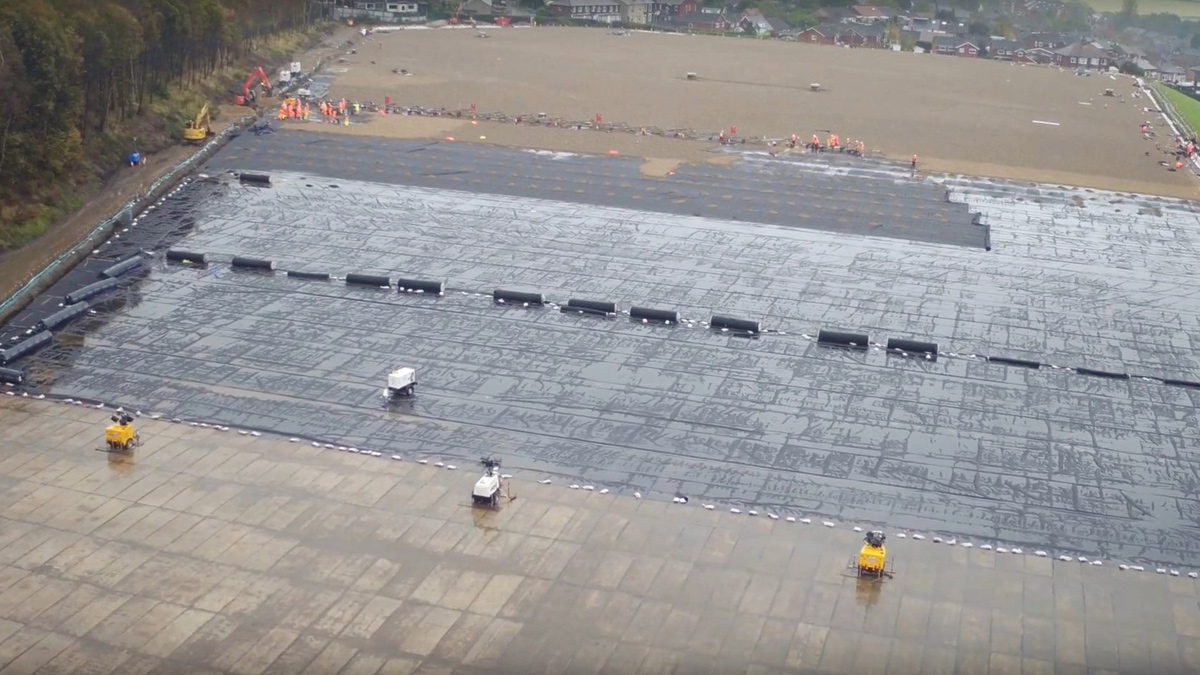

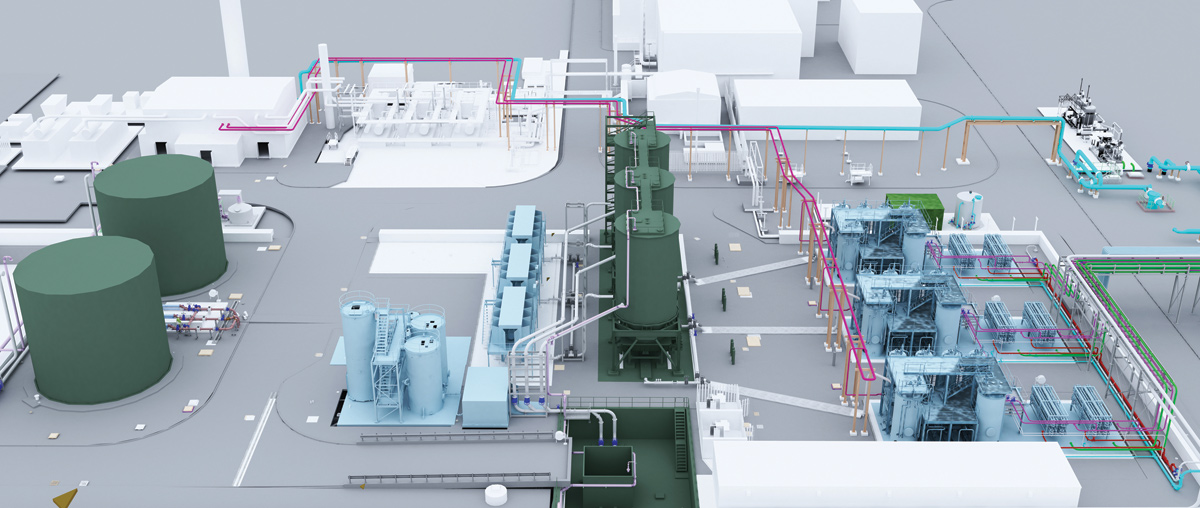

“For us, the focus is always on finding the most reasonable and resource-saving solution for the plant in question and then ensuring that the new actuation technology is implemented smoothly and on time,” explains Thomas Knecht, Director After Sales & Service at AUMA. The AUMA service team has already completed a large number of successful retrofit projects in a wide range of plants, from power generation to water and wastewater treatment and tank farms.

Further information on the AUMA Retrofit Service, along with practical project examples, can be found online at retrofit.auma.com.

For more information contact AUMA Actuators Ltd | +44 (0) 1275 871141 | www.auma.co.uk

About AUMA Actuators Limited

Based in Clevedon, near Bristol, AUMA is the UK subsidiary of the global AUMA Reister GmbH and Co., the world’s largest manufacturer of electric valve actuators, operating on every continent, with 2,300 employees in 30 locations.

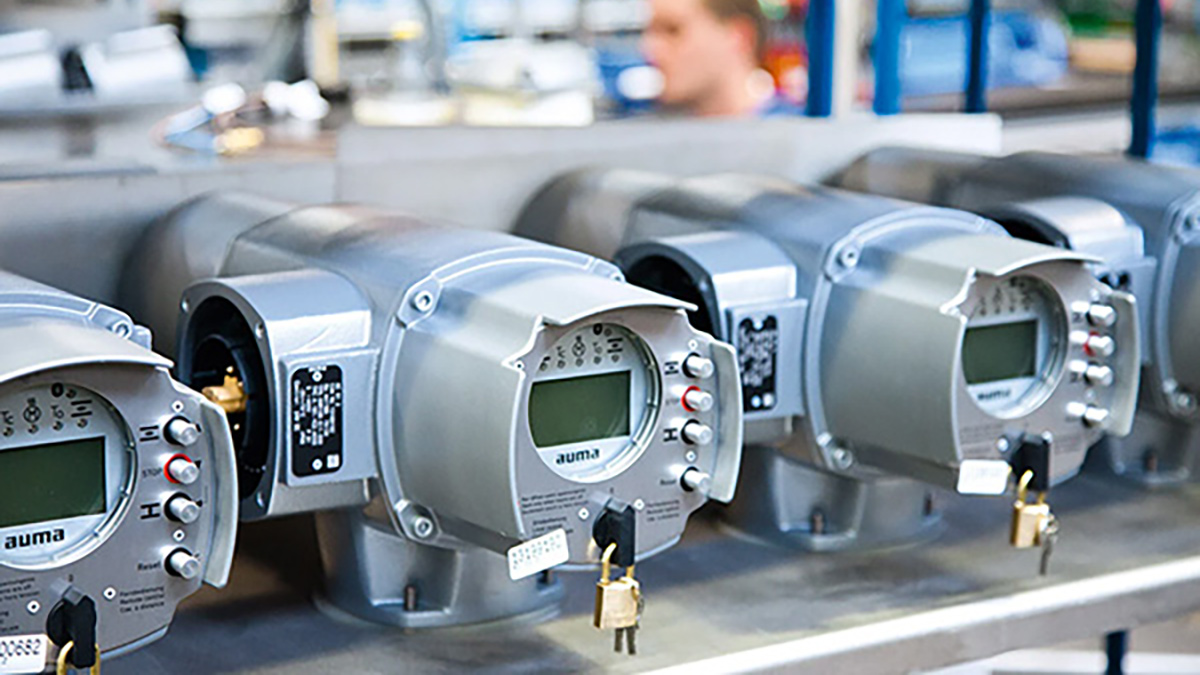

AUMA is the world leader in modular electric valve actuators and gearboxes, supplying a full range of actuators right across the process, water, petrochemical and energy sectors. AUMA manufactures robust, reliable equipment with sophisticated control and connectivity options, backed up with exceptional service support.

AUMA benefits include:

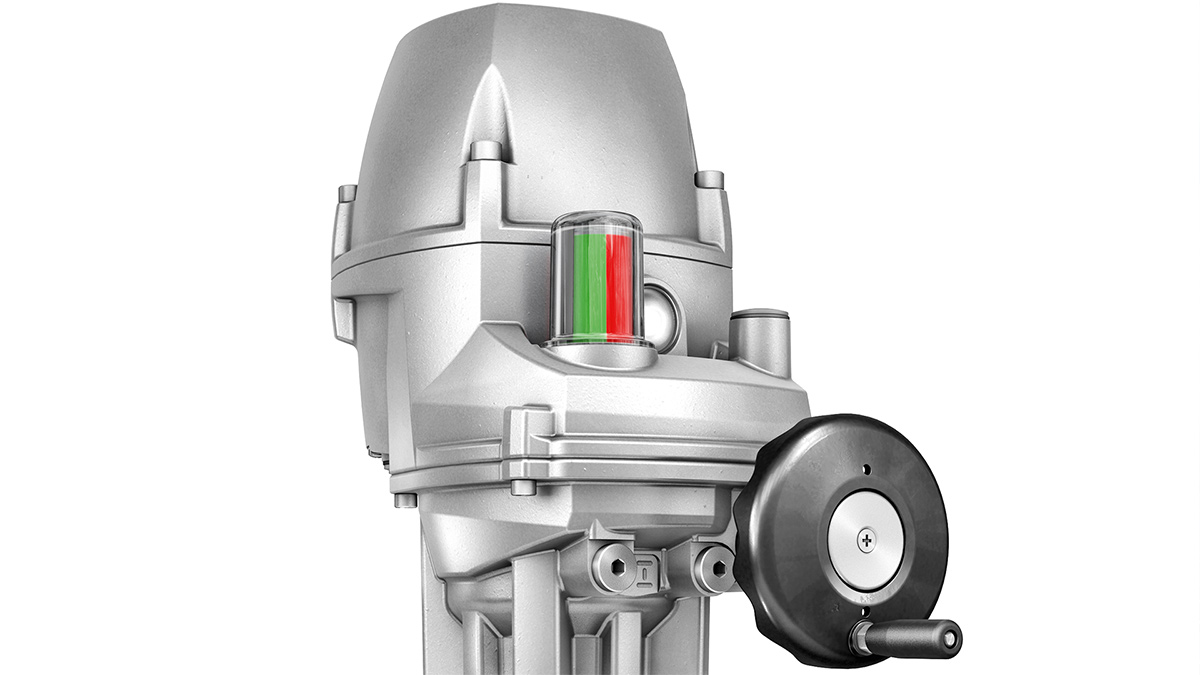

- Rugged and reliable products.

- Double-sealed actuator housing to protect the electronics.

- Tough and resilient finish.

- Powerful, with multi-turn actuators from 7 to 59,000 ft lb (10 to 80,000 Nm) and thrust acceptance up to 900,000 lbs (4,000 kN) and part-turn actuators from 18 to 498,000 ft lb (25 to 675,000 Nm).

- Worldwide availability and support.

- Modular, user-friendly design which provides key benefits such as:

- Supply subcontractors with the appropriate components to allow-pre-assembly

- Reduce time on site – plug and play

- Mount gearboxes up to 100m from the actuator controls to aid access and minimise health and safety risks

ACE Technician Scheme

ACE Technicians can be in-house or part of your service organisation. The ACE (AUMA Certified Engineering) programme has three levels, allowing operatives to be certified for installation or for advanced configuration, troubleshooting and repair. The ACE scheme means that you can have trained, card-carrying AUMA ACE Technicians as part of your own organisation or as part of your service partner’s staff, working in partnership with the service offered by AUMA UK’s head office in Bristol.