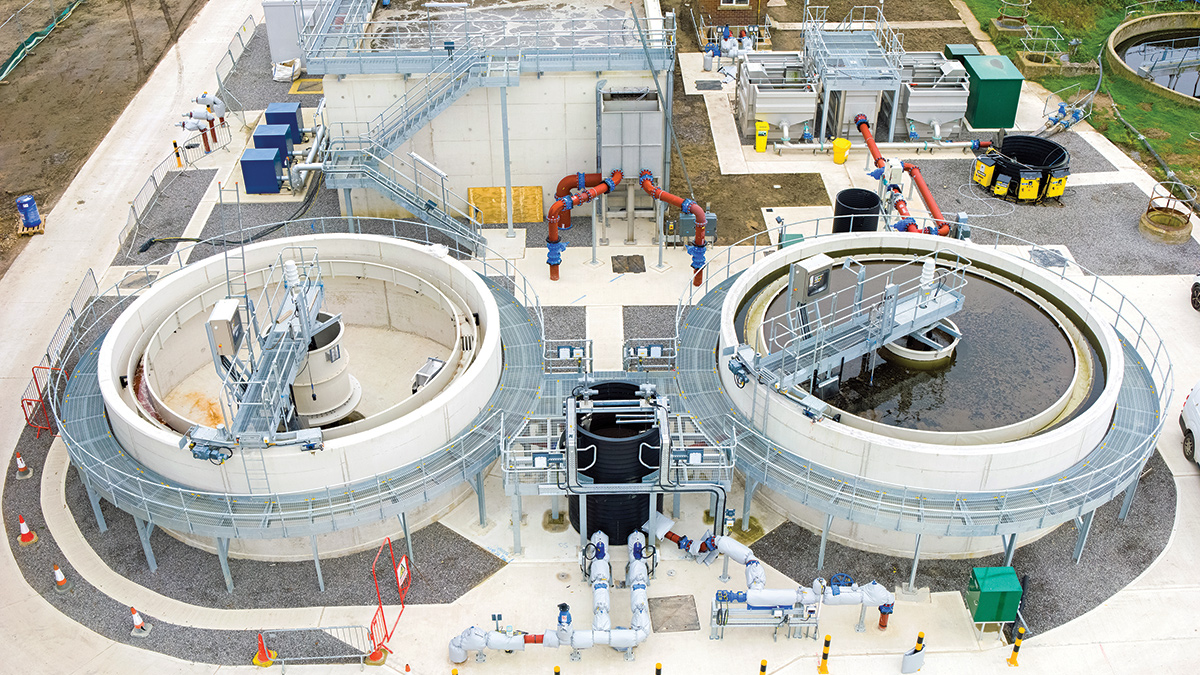

Tamlaght is a small village in County Fermanagh, strategically located just off the Belfast Road between Enniskillen and a growing cluster of expanding settlements including Lisbellaw (3 miles), Maguiresbridge (8 miles), Brookeborough (10 miles), and Lisnaskea (13 miles). This settlement pattern underlines the strategic importance of Tamlaght Wastewater Treatment Works (WwTW), making it a key asset in supporting both existing demand and future development in the region. As part of their six-year business plan (Price Control Period 2021-2027) and infrastructure programme, NI Water invested £3.7m to upgrade Tamlaght WwTW with modern new infrastructure and cutting-edge technology. The project introduced state-of-the-art treatment tanks, along with advanced electrical and mechanical systems to provide a robust future proof wastewater treatment solution all delivered within the existing site footprint.

Existing treatment process

The original Tamlaght WwTW was designed for a population equivalent (PE) of 790, treating a current PE of 481 in 2019 with growth projections to 527. Despite having apparent headroom capacity, the works consistently failed to meet planning and discharge consent conditions, preventing further catchment development. The water order consent standard for the existing works was 40:60:10 mg/l (BOD:SS:Ammonia), however this was later relaxed by Northern Ireland Environment Agency (NIEA) to 40:60 mg/l for the future PE.

The existing works comprised an automatically raked inlet screen, compact activated sludge plant with oxidation tank and final settlement tank, control kiosk, and final effluent measurement flume.

[caption id="attachment_25920" align="alignnone" width="1200"] The existing wastewater treatment facility at Tamlaght: (top left) Overview of site, (top right) the existing compact activated sludge plant, (bottom left) the existing works entrance and (bottom right) the existing inlet works - Courtesy of DLJ Water Ltd[/caption]

Project drivers

The wastewater treatment works at Tamlaght had been in operation for nearly 40 years, with NI Water investing continually in maintenance to sustain discharge compliance.

Over time, rising population demands placed additional pressure on the site, while ageing assets neared the end of their design life and parts of the site became increasingly vulnerable to flooding.

Although the works retained sufficient hydraulic headroom, it frequently breached consent conditions, restricting further catchment development. In addition, the condition of the site, the increased population equivalent, and evolving regulatory requirements all became significant drivers for investment.

The key project drivers can be summarised as follows:

Future growth: Support the anticipated growth of the local population in the Tamlaght catchment area, ensuring infrastructure meets requirements for a 25-year design horizon.

Future-proof design: Deliver a flexible design that can accommodate future extensions, modifications in flows, loads, or regulatory consents with minimal disruption.

Regulatory compliance: Achieve compliance with the new NIEA discharge consent standard of 40:60 mg/l (BOD:SS) and deliver environmental improvements through enhanced water quality discharge to Lough Erne in accordance with the Water Order Consent standard and Urban Wastewater Treatment Regulations (NI) 2007.

Environmental protection: The treated final effluent is discharged into a tributary of Upper Lough Erne, a sensitive waterbody of high ecological value and recreational importance. Maintaining consistently high effluent quality was critical to protecting local watercourses and the wider rural ecosystem, supported by an environmental management pump station to ensure long-term protection.

Operational efficiencies: Drive reductions in operational interventions and maximise overall efficiency, while supporting sustainability through:

Blower energy consumption.

Minimised visual impact.

Reduced waste and disruption.

Enhanced noise and odour control.

Improved air quality.

Positive socioeconomic outcomes.

Flood resilience: Ensure that all new structures and equipment are constructed above the Q100 flood level, mitigating the risk of future flooding at the Tamlaght WwTW site.

Existing process: Phased construction of the new treatment works on a constrained site, while maintaining full operation of the existing process to ensure all discharge consent standards are consistently met throughout the works.

[caption id="attachment_25935" align="alignnone" width="1200"] Construction of the storm tank - Courtesy of DLJ Water Ltd[/caption]

Project delivery team

DLJ Water Ltd, a highly experienced collaborative joint venture between Deane Public Works Ltd, Lowry Building & Civil Engineering Ltd, and Avove Ireland (formerly Jacopa Ltd), was appointed as the Principal Contractor and Principal Designer.

The multi-disciplinary joint venture specialises in civil, process, and MEICA design and engineering services for water and wastewater treatment plants and associated infrastructure assets, with full responsibility for delivering a turnkey MEICA and process design-and-build solution for the new Tamlaght works on time and within budget.

Tetra Tech RPS was appointed by NI Water as Project Managers and worked collaboratively with DLJ Water to ensure the successful delivery of the scheme. For the Tamlaght works, the process and MEICA designs were developed by treatment process specialist and joint venture partner Avove Ireland. Deane Public Works led the JV design alignment process and, together with the expert supply chain, oversaw the civil design and construction requirements.

Early contractor involvement

DLJ Water was awarded an NEC4 (Option A) Early Contractor Involvement (ECI) contract by NI Water in June 2022 for the multi-disciplinary design, construction, commissioning, and testing for a replacement treatment works at the existing Tamlaght WwTW site.

The extensive ECI phase allowed DLJ Water to align resources, integrate objectives, and gain an early understanding of the key project drivers in collaboration with NI Water, their project management team, and other key stakeholders. This proactive approach facilitated enhanced collaboration, innovation, and value, while improving operational efficiency and reducing whole-life costs for the project.

[caption id="attachment_25931" align="alignnone" width="1200"] (left) Storm tank installation and (right) MCERT installation - Courtesy of NI Water[/caption]

Regular design review and HAZOP (Hazard and Operability) meetings were critical throughout the ECI and construction phases to develop sequencing, review progress, identify potential risks, and ensure that design decisions met safety, operational, and regulatory requirements. These workshops provided the Integrated Project Team with the opportunity to review the proposed completed works, support clash detection, and advise on design changes or pinch points.

The collaborative working relationship developed between DLJ Water, NI Water, Tetra Tech RPS, and the wider supply chain through the ECI process and subsequent construction phase, facilitated greater innovation and the successful delivery of a robust, sustainable, modern wastewater treatment solution. The facility is capable of meeting stringent consent standards, protecting the environment and addressing future catchment needs over a 25-year projection horizon, meeting NI Water’s targets.

Tamlaght WwTW - Supply chain - key participants

Client: NI Water

Principal contractor & designer: DLJ Water Ltd

Deane Public Works Ltd

Lowry Building & Civil Engineering Ltd

Avove Ireland

Project managers: Tetra Tech RPS

MEICA/process designer & contractor: Avove Ireland

Civil/geotech/structural/temporary works design & construct: Deane Public Works Ltd

Piling: Larsen Piling

Steelwork: LA Steel Fabrications Ltd

Formwork & concrete: TK Concrete

Precast concrete/concrete: Tracey Concrete

Rotating biological contactors: KEE Process Ltd

Electrical/ICA/MCC: Pronto Automation Systems Ltd

Inlet screen: Hydro International Ltd (M and N Electrical and Mechanical Services)

Pipework: APP Fusion Group

Water booster set: Dutypoint Ltd

Fencing: O’Neill Fencing

[caption id="attachment_25918" align="alignnone" width="1200"] Inlet screens installation - Courtesy of DLJ Water Ltd[/caption]

MEICA/process design

Avove Ireland designed a full turnkey MEICA and process replacement plant for Tamlaght Wastewater Treatment Works, utilising best technologies and techniques to minimise operational expenditure while accommodating a projected population equivalent (PE) of 527.

The limited site footprint for the replacement works, combined with the requirement to maintain treatment capabilities in line with current discharge consent standards during construction, presented a significant challenge. These space constraints were addressed by optimising the layout within the available footprint and incorporating compact treatment technologies, including rotating biological contactors (RBCs) and package process units.

Additionally, the inlet works were non-compliant with NI Water Asset Standards, lacked flow measurement and control, and routed all flows to the CASP via supplementary interstage pumping.

Inlet works

The MEICA and process design for the new Tamlaght works encompassed the supply, installation, and commissioning of a new inlet works channel, featuring a 6mm perforated screening unit, with operation controlled via differential level measurement. Screenings are discharged to wheelie bins through a dedicated chute. The screening unit is equipped with frost protection cycles and a potable water supplied screening wash system from the site booster set, ensuring reliable operation under all seasonal conditions.

[caption id="attachment_25929" align="alignnone" width="1200"] Completed inlet works - Courtesy of NI Water[/caption]

The inlet channel is equipped with an emergency 10mm manual rake bypass screen and level probe detection, with influent diverted back to the flow control chamber for treatment. The bypass channel also incorporates an emergency overtop facility and a screenings launder, ensuring continued operation and safeguarding the downstream process under exceptional conditions.

A flow control channel has been incorporated into the inlet works to accommodate flows exceeding Formula A, with measurement provided via a level transducer, before onward passage to the 6mm screening unit and discharge to the nearby watercourse.

Storm tank

The system also includes full flow to treatment (FFT) overflow control, with flow measurement via level transducer, directing any excess FFT to the storm tank to maintain process stability and protect downstream infrastructure.

The storm tank provides storm influent retention and additional 6mm overflow screening, with level transducer monitoring for Event Duration Monitoring (EDM) and protection. Additional safeguard is provided by backup float switch activation. A storm water return pumping station, complete with associated pipework and valves, utilises two VSD-controlled storm water pumps operating in duty/standby mode, with flow measurement installed on the return main to ensure controlled and reliable return of storm flows to the treatment process.

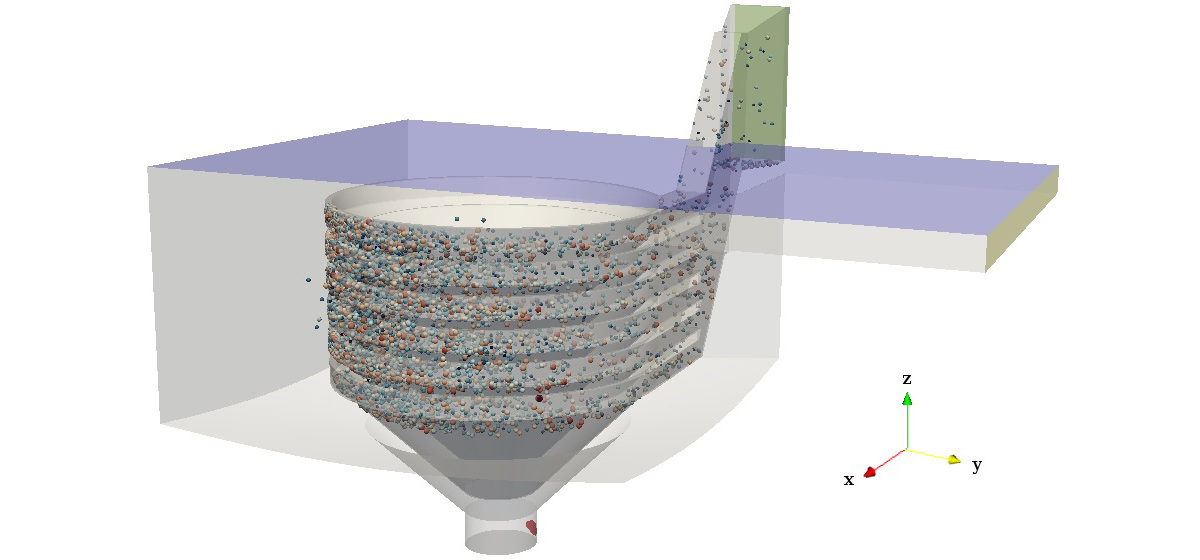

Rotating biological contactors (RBCs)

Flows up to full flow to treatment (FFT) are treated via two package rotating biological contactors, each complete with drive systems, media banks, and protective covers. Integral to each RBC is a primary settlement tank located upstream of the biological contactors and a final settlement tank positioned downstream of the biological treatment zone. Each RBC is designed to process up to 50% of the maximum FFT, ensuring redundancy and operational flexibility.

[caption id="attachment_25930" align="alignnone" width="1200"] The new rotating biological contactors - Courtesy of NI Water[/caption]

Each RBC is equipped with a dedicated sludge management system, comprising sludge draw-off hydrostatic pressure pipes positioned at intervals along the RBC length and terminating in a common manifold fitted with Bauer couplings and caps for removal by sludge tanker. A designated road tanker loading point with Bauer connection and spill containment apron is provided to facilitate safe and efficient sludge handling.

EMS Pumping Station

The site incorporates an Environmental Management System (EMS) pumping station, comprising a single submersible pump operating on duty-only mode. The pumping main conveys captured influent from the designated EMS area back to the treatment process at the flow splitter chamber, ensuring controlled return and integration with the overall wastewater treatment system.

Outfall

Process flows from each RBC are directed to a common discharge chamber and onward to an MCERT-compliant measurement chamber, which incorporates a thin-plate weir for regulatory flow monitoring of the final effluent prior to discharge to the undesignated watercourse. The MCERT chamber is also equipped with a turbidity probe for solids monitoring, a temperature probe, and a level probe to support comprehensive effluent data analysis and regulatory compliance reporting.

All flows from the process treatment, excess Formula A (F’A’), and storm water retention are combined in a common discharge chamber and released to the nearby watercourse, ensuring controlled and compliant effluent conveyance.

[caption id="attachment_25922" align="alignnone" width="1200"] MCERT installation - Courtesy of NI Water[/caption]

Incoming water supply

The upgrade includes a new incoming mains water supply with metering equipment, bypass facility, and location marker. A double check valve with inspection chamber is provided upstream of the meter for backflow prevention. A site potable washwater booster package plant was installed to service all wash-down points, comprising a duty/standby booster set housed within a compartmentalised GRP kiosk. Hosing and flushing facilities are provided within operational range of all process units and pumping stations to ensure effective cleaning and maintenance access.

Control system & power supply

A new intelligent MCC, including generator connection and automatic changeover facilities, has been provided, supplied by a new NIE power connection in accordance with NIE design specifications and direction.

The site is equipped with comprehensive telemetry, control, and instrumentation systems, including PLC and HMI functionality to enable real-time monitoring, operational control, and data management across all process units and pumping stations.

Civil/structural design & construction

Joint Venture partner Deane Public Works led the civil, structural, and geotechnical design and construction process for the Tamlaght works.

The scope included initial enabling and investigatory works during the ECI stage, followed by the detailed design for construction.

The civil and structural design comprised the overall site layout, including process pipework, ducting, site drainage, and hydraulic design. It also encompassed new inlet works with screening plant, Formula A and FFT flow controls, a new RBC unit layout with flow split chamber, a storm pumping station, MCC trench, grit chamber, and final effluent and flow measurement chambers. Additional civil design requirements included the structural design of reinforced concrete structures, such as pile slabs.

[caption id="attachment_25931" align="alignnone" width="1200"] (left) Storm tank installation and (right) MCERT installation - Courtesy of NI Water[/caption]

The existing Tamlaght WwTW site was constrained by its small footprint, containing a compact activated sludge plant (CASP) and inlet works with an above-ground gravity sewer. Limited space and the single-structure CASP required the proposed assets to be constructed fully offline while maintaining CASP operation. Furthermore, the above-ground alignment of the incoming sewer prevented it from crossing the existing site access, resulting in the inlet works being located along the southern boundary of the site, which in turn dictated the positioning of all other proposed assets.

A key civil consideration was ensuring the design of the new structures focused on elevating them relative to the existing site to reduce flood risk while ensuring gravity inflows to the WwTW were maintained. Formation levels were carefully set to preserve the correct hydraulic profile throughout the site. The presence of an existing floodplain, with Q100 flood levels approximately 1m above the common ground, presented additional hydraulic and level constraints. The proposed design addressed these challenges by protecting the assets from flooding while maintaining a fully gravitational hydraulic system for process flows.

Site investigations identified the presence of extensive peat within the substrata. Following a detailed review of the ground conditions, it was determined that deeper site structures would be supported using a mini-pile and pile slab arrangement. Temporary works cofferdams with hydraulic bracing were designed and installed to allow the deep storm tank construction in the challenging soil conditions of extensive peat (SPT N-value =0) extending to 16.6m below the surface.

For the site road and hardstanding, a geogrid solution was implemented using a floating road design. This approach allowed finished ground levels to be raised to the Q100 flood level while minimising backfilling, thereby providing effective flood protection for both the site roads and the process assets.

Adequate flexibility was incorporated into all interconnecting pipework to minimise the impact of any differential settlement between pile-supported structures.

[caption id="attachment_25919" align="alignnone" width="1200"] Completed flume - Courtesy of DLJ Water Ltd[/caption]

Public/stakeholder engagement

Collaboration was integral to the planning, design, and construction of the new Tamlaght WwTW. NI Water, the DLJ Water Team, and Tetra Tech RPS worked together to develop a proactive communications and public relations strategy, ensuring that residents and the wider public were kept fully informed about the installation and project progress.

Continued regular stakeholder engagement throughout the project helped to prevent delays, with early and effective liaison ensuring that no issues arose from stakeholder concerns.

Challenges/constraints

DLJ’s Integrated Project Team overcame significant constraints and challenges through a collaborative approach, delivering an operationally efficient facility, including:

The project faced challenges in securing suitable land for the new site. By leveraging local knowledge, DLJ successfully identified and acquired adjacent land, allowing the project to progress as planned.

Phased demolition of existing structures, combined with the staged construction of the new treatment works, further restricted the already confined site.

Maintaining the existing process in full operation throughout the works to ensure compliance with all discharge consent standards.

A delicate and prolonged ‘seeding’ period was required for biomass growth in the bio-contactor zone of the RBC, a process that was highly dependent on weather conditions.

A strategic ‘seeding’ process was implemented using both existing infrastructure and new assets, ensuring compliance while effectively synchronising biomass development.

Periods of hyper-inflation in material and labour costs during the design phase.

Supply chain delays during a period of significant uncertainty, driven by Brexit and volatile market conditions.

[caption id="attachment_25936" align="alignnone" width="1200"] Demolition of the existing CASP - Courtesy of DLJ Water Ltd[/caption]

The treated final effluent discharges to a tributary of Upper Lough Erne, a water body of high ecological sensitivity and recreational value, designated as a Ramsar site, Special Area of Conservation (SAC), and Special Protection Area (SPA).

Maintaining consistently high effluent quality is critical for compliance with statutory water quality objectives, the protection of local watercourses, and the safeguarding of the wider Upper Lough Erne catchment, an ecosystem of international significance.

This challenge was addressed through the implementation of advanced treatment processes, robust compliance monitoring, and resilient supporting infrastructure. Process optimisation secured adherence to stringent discharge standards, while the integration of an environmental management pumping station provided additional operational control and contingency against water quality risks. Continuous monitoring, proactive maintenance, and best-practice operational management further enhanced system reliability, ensuring the long-term protection of both local watercourses and the wider catchment.

Although compact, space-saving RBCs were incorporated into the design, the additional treatment capacity necessitated a substantial footprint within the existing NI Water site, where space for spoil storage or construction materials was limited. To address this constraint, a ‘just-in-time’ delivery approach was implemented, minimising on-site storage requirements and optimising construction logistics.

The new infrastructure was designed and elevated to ensure that all structures and equipment are positioned above the Q100 flood level, providing protection of critical assets during potential flooding events at the Tamlaght site.

[caption id="attachment_25923" align="alignnone" width="1200"] Completed storm tank - Courtesy of NI Water[/caption]

Completion

Despite the challenges encountered, the new Tamlaght WwTW was completed with full site-wide testing and commissioning successfully undertaken ahead of handover to NI Water in February 2025, on time and within budget.

The new works was rigorously tested and commissioned before handover and is now producing excellent results, comfortably meeting the NIEA final effluent quality standards of 40 mg/l BOD, 60 mg/l suspended solids respectively.

This innovative wastewater treatment solution, designed, constructed, and commissioned by DLJ Water, offers the capability, flexibility, and reliability to meet future catchment needs over a 25-year projection horizon. It will support sustainable development in the Tamlaght area while providing increased environmental protection through enhanced water quality for the adjacent Upper Lough Erne.

The upgrade of Tamlaght WwTW provided a valuable opportunity to modernise a small rural wastewater asset, safeguard environmental integrity, and ensure compliance with evolving regulatory standards. By leveraging lessons learned from comparable projects, ultimately this project sets a precedent for how rural treatment works can be revitalised to deliver long-term benefits for both the environment and the local community.

NI Water Senior Project Manager, Michael Donnelly, commented on the benefits of the project for the local community and environment:

“The £3.7m investment in the new Wastewater Treatment Works at Tamlaght has delivered the latest safe and efficient technology in wastewater treatment that will protect the local environment and surrounding countryside, providing headroom within the works that will cater for growth in the community.”