MGF Ltd

Excellent Engineering Carried out by MGF for Ipswich Tidal Barrier

Excellent Engineering Carried out by MGF for Ipswich Tidal Barrier

SUPPORTING THE IPSWICH TIDAL BARRIER

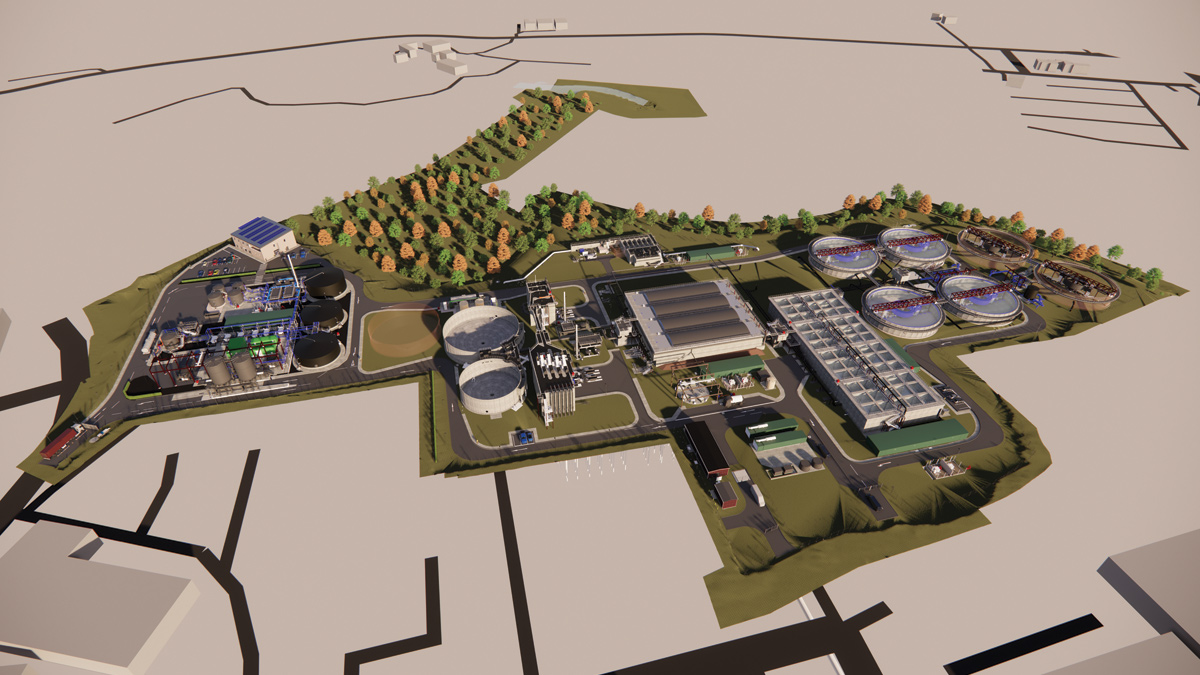

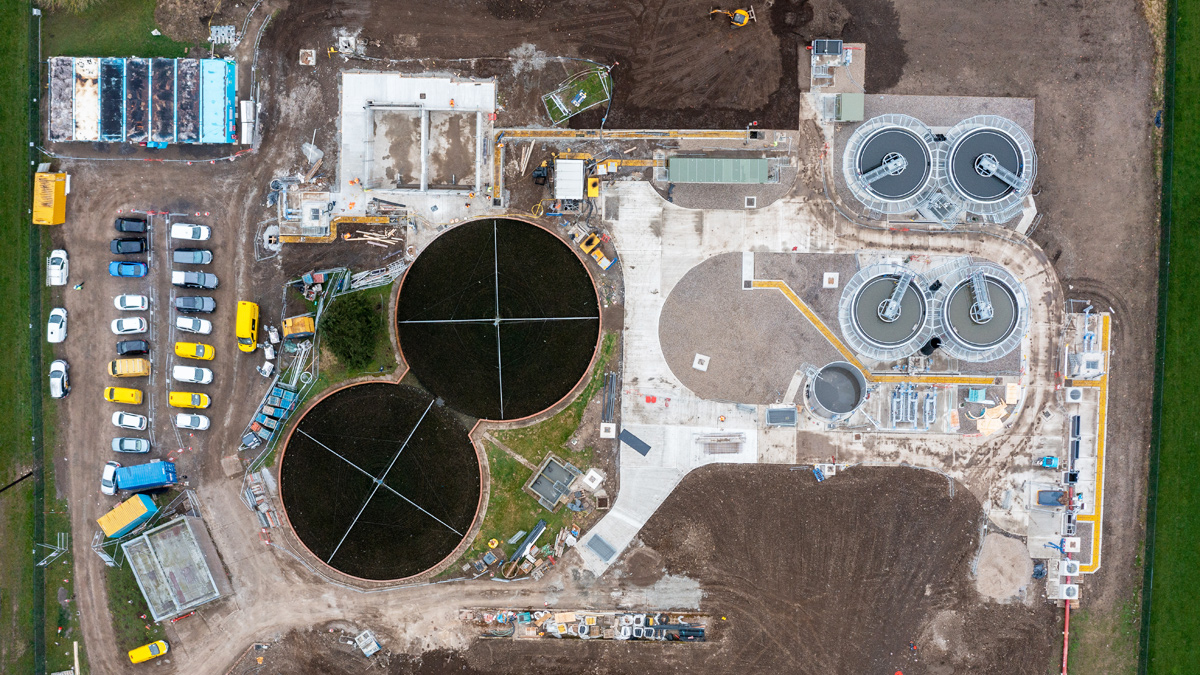

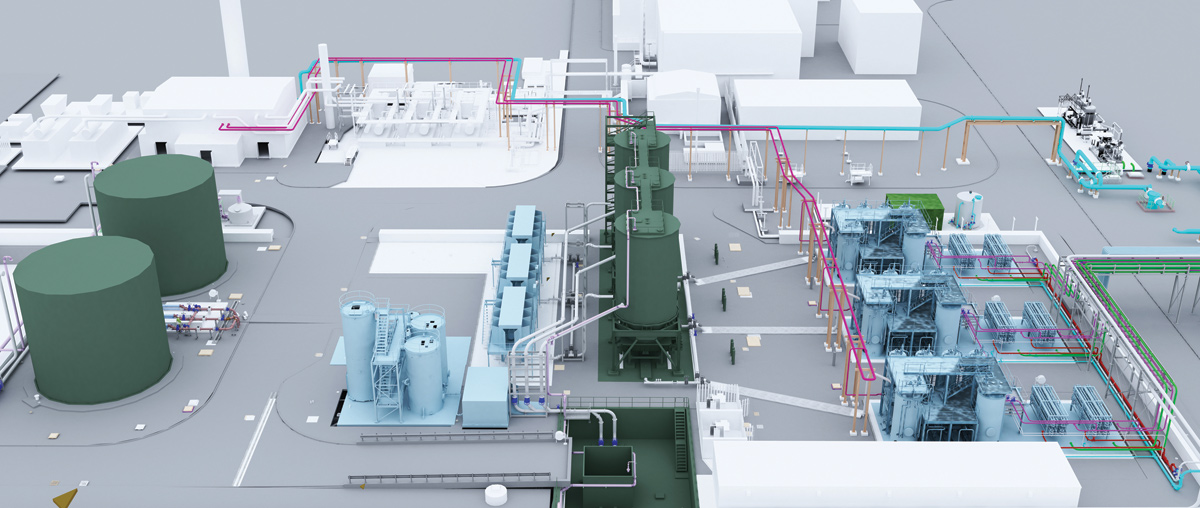

Ipswich’s position on the estuary of the River Orwell in Suffolk makes it susceptible to fluvial and tidal flooding. The Ipswich Tidal Barrier Project is the final element of a £58 million programme of work. The Environmental Agency conducted the works to upgrade the flood defences on the banks and the Port of Ipswich itself. The Tidal Barrier works have required approval by the Secretary of State for the Environment Food and Rural Affairs. This was due to the barrier permanently affecting the right of navigation through the new cut of the River Orwell. This was done via a parliamentary order under the Transport and Work Act.

The Ipswich Tidal Barrier order was made in August 2012.

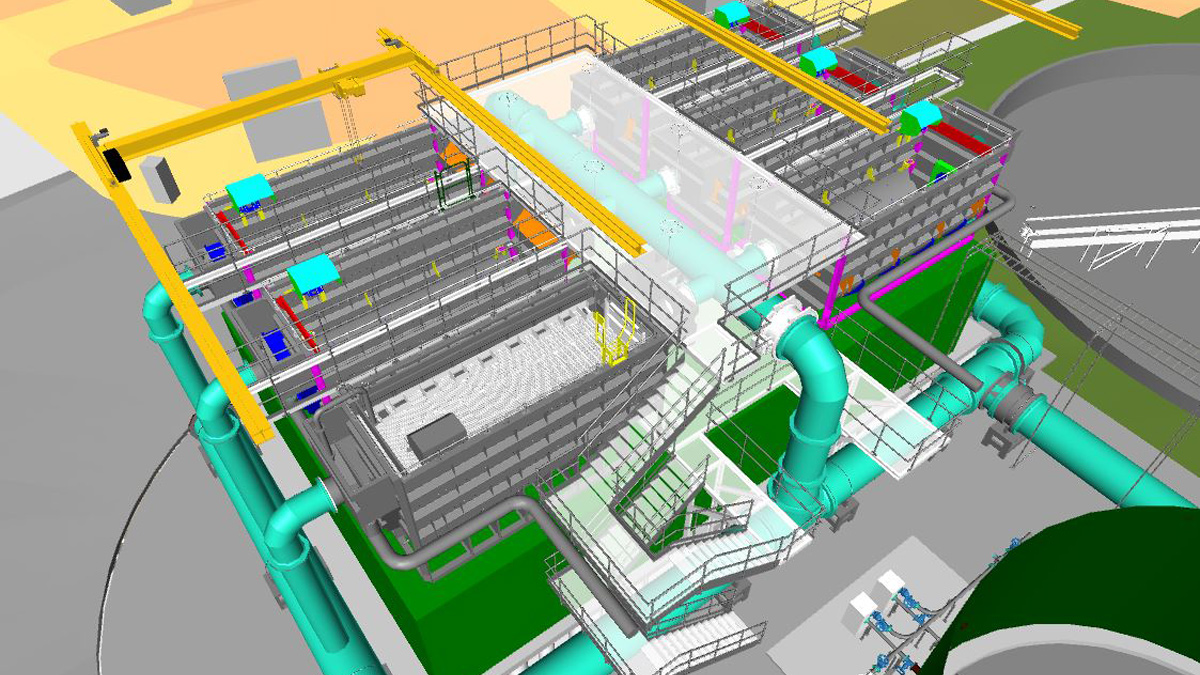

Working with design and build contractor VBA, a VolkerStevin, Boskalis Westminster and Atkins joint venture, & specialist consultant Tony Gee and Partners, the Ipswich Tidal Barrier temporary works is the most advanced design delivered by MGF’s in-house design engineers.

THE SOLUTION

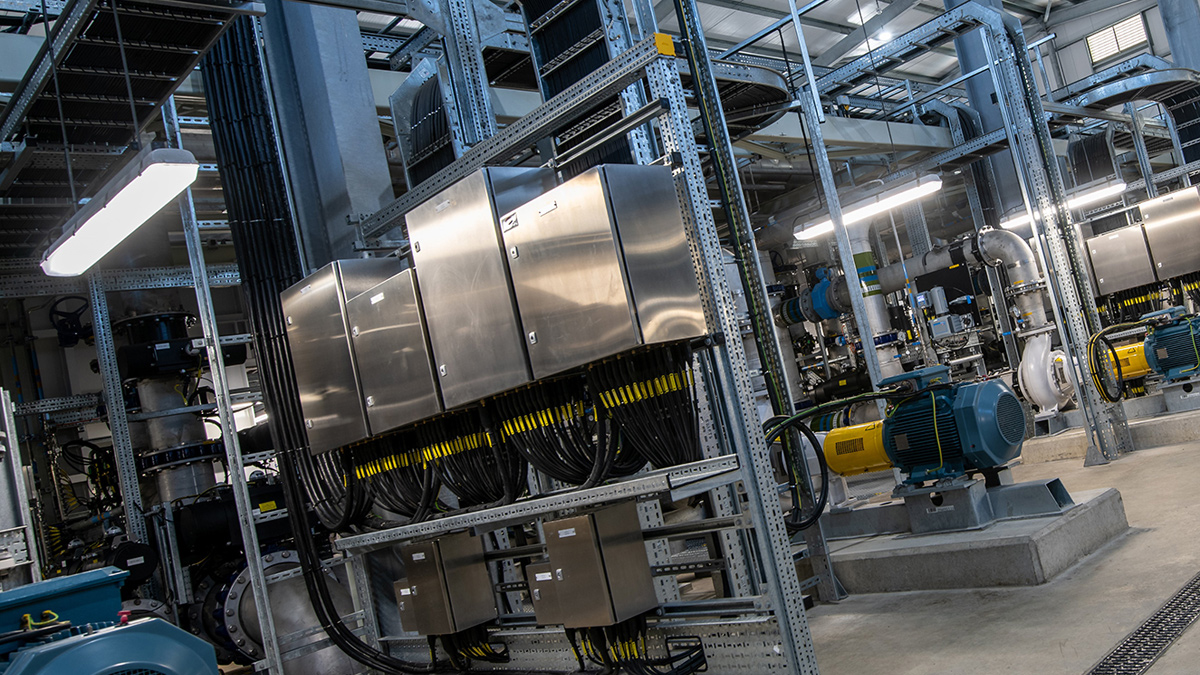

MGF offered a complete temporary works solution that delivered on cost, time, safety, quality, service and sustainability. One of the key differentiators in MGF’s service offering is the capability to manufacture bespoke components.

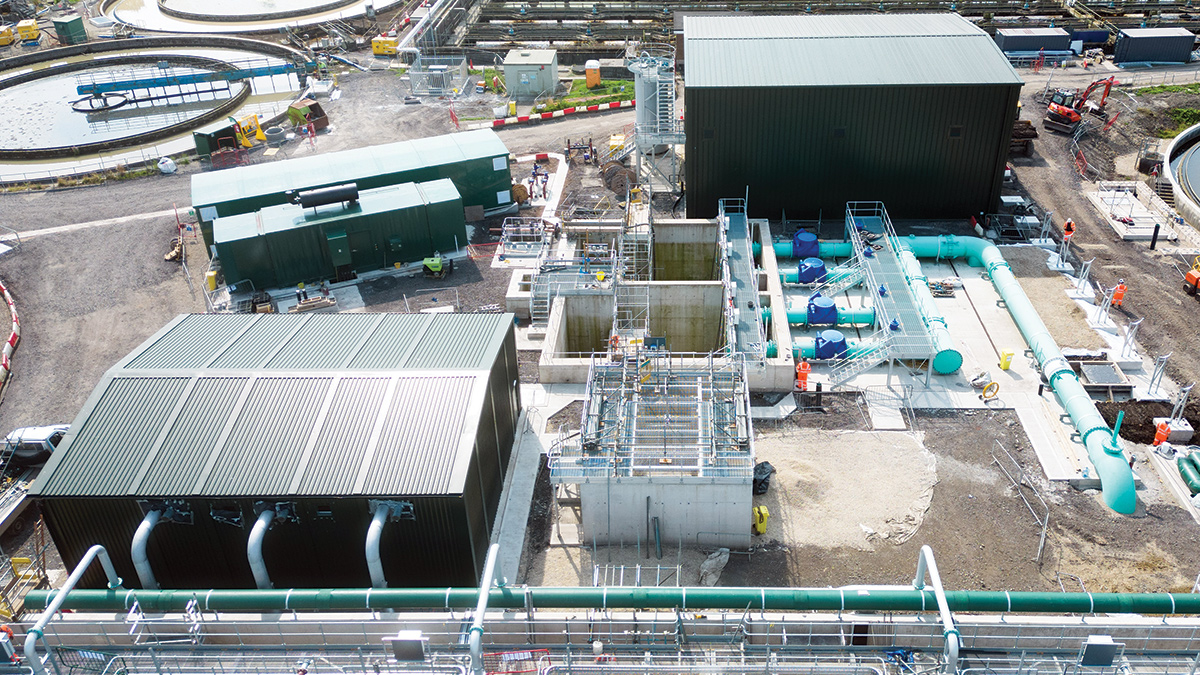

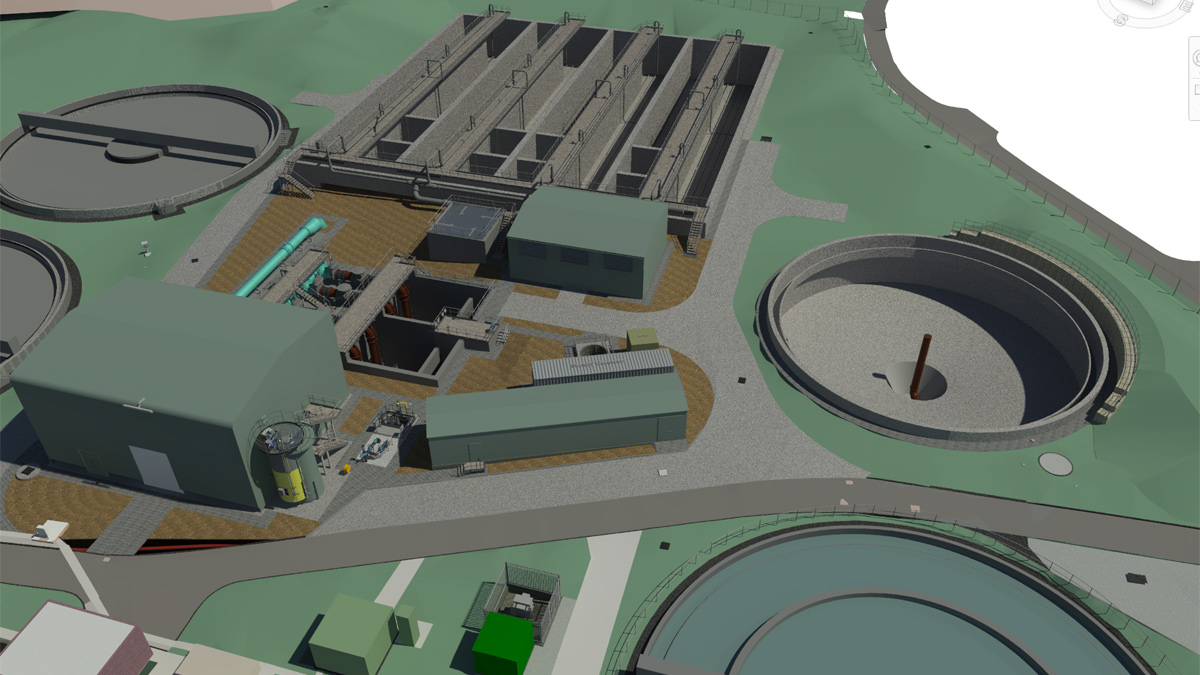

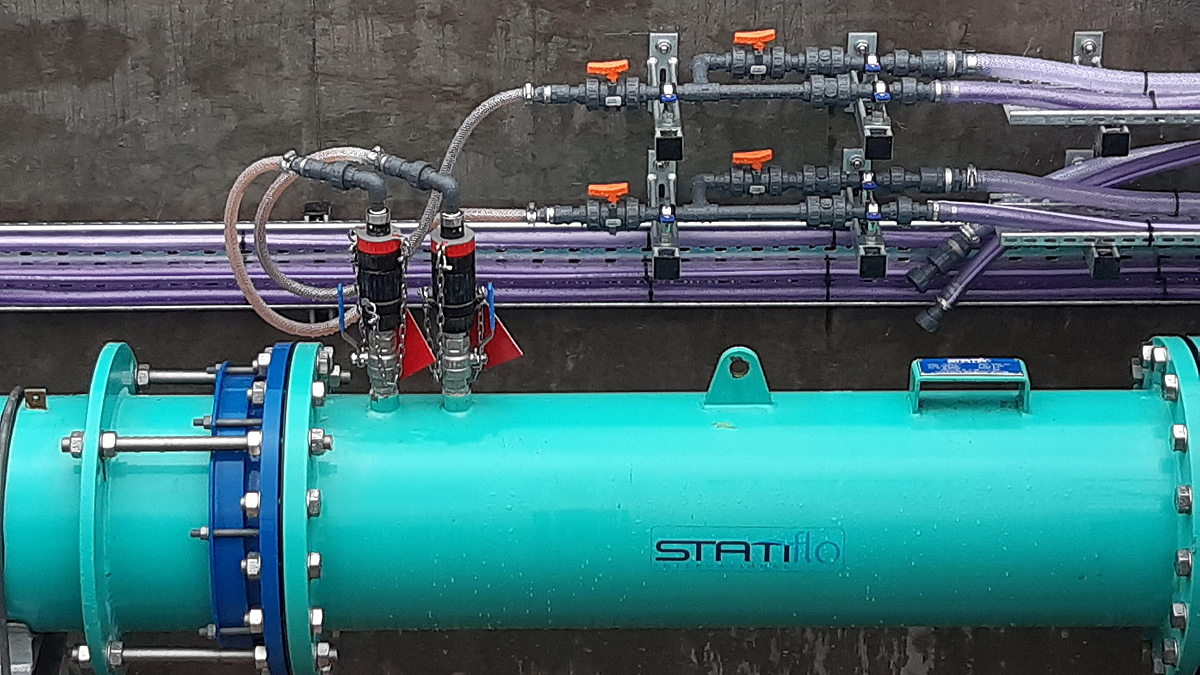

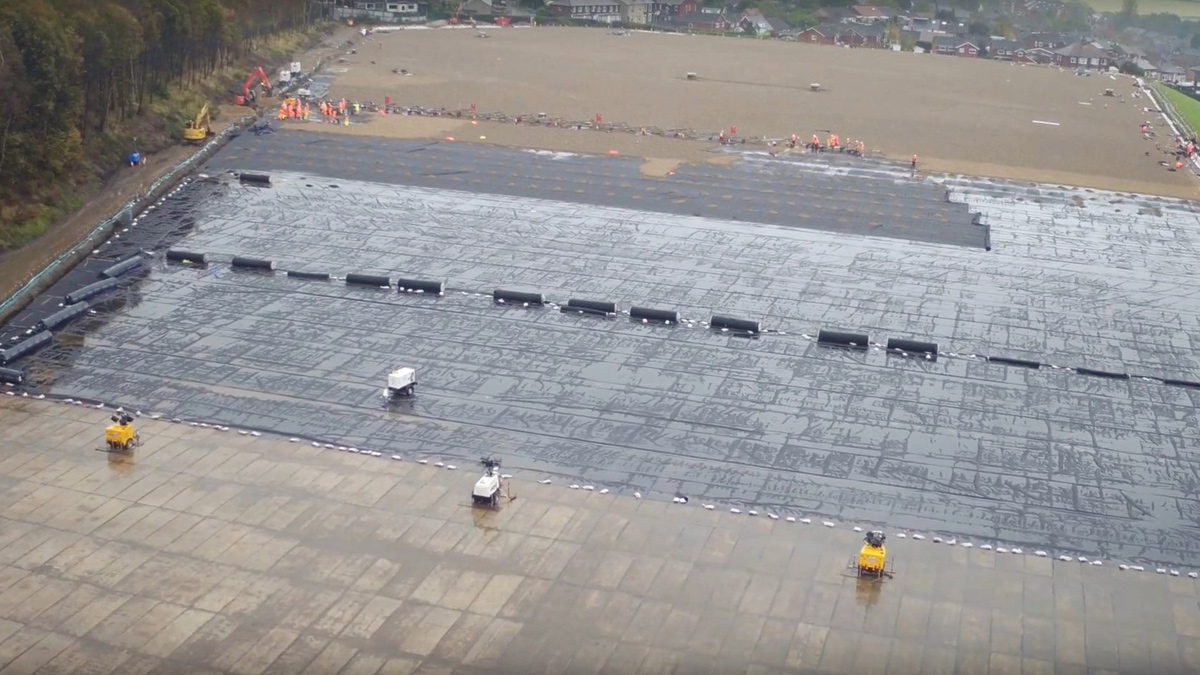

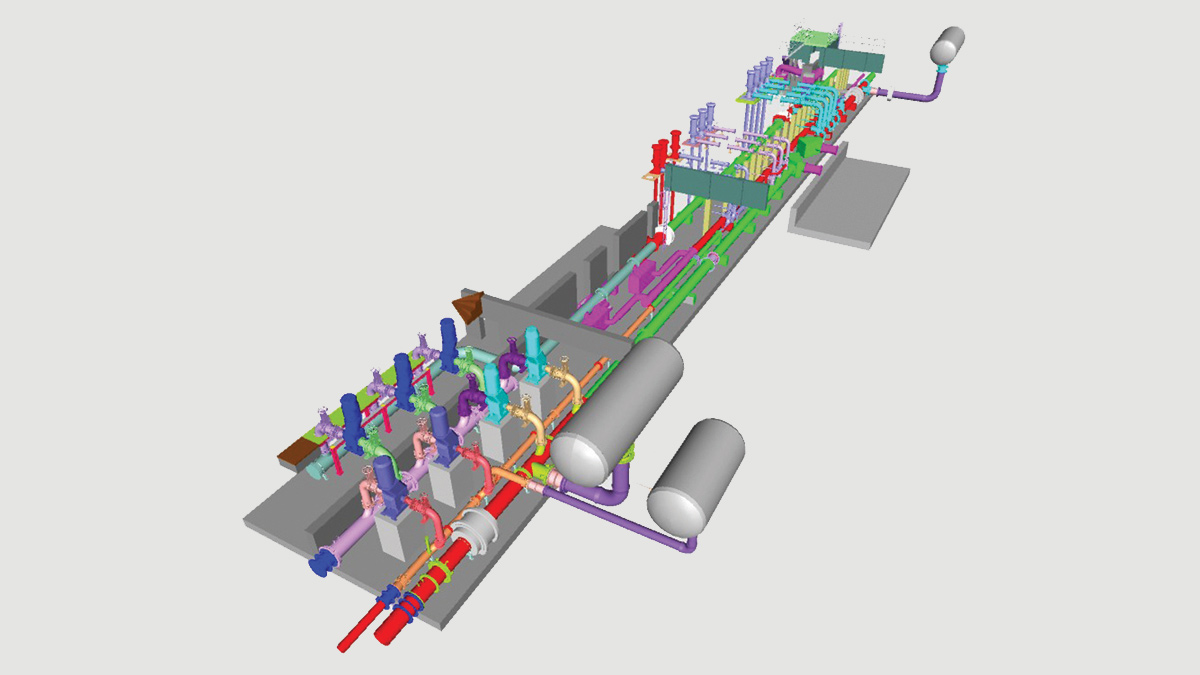

158 tonnes of fabricated steel were installed between the east and west banks of the port. The 30m x 30m excavation allows a safe working space to construct the colossal tidal barrier. Bespoke sections required just two weeks to fabricate and deliver direct to site from MGF’s Wigan workshop.

Stephen Barker, Engineering Director, MGF Ltd said:

“This is a high-risk and complex project due to the high loads imposed by the river and the variation in tidal conditions. This resulted in significant imbalances on each side of the wall. We twinned our modular 406UC brace; however, we manufactured 15m lengths to suit construction requirements and modified the joints to increase their capacity. The imbalanced loads caused an issue with the frames pulling apart. We designed a 28m long 762 × 762×25.4 circular hollow section to tie the north and south waling beams together. The rest of the support consisted of 762×25.4 circular hollow sections as knee braces, with four at 15.60m long and four at 6.00m long.”

THE VERDICT

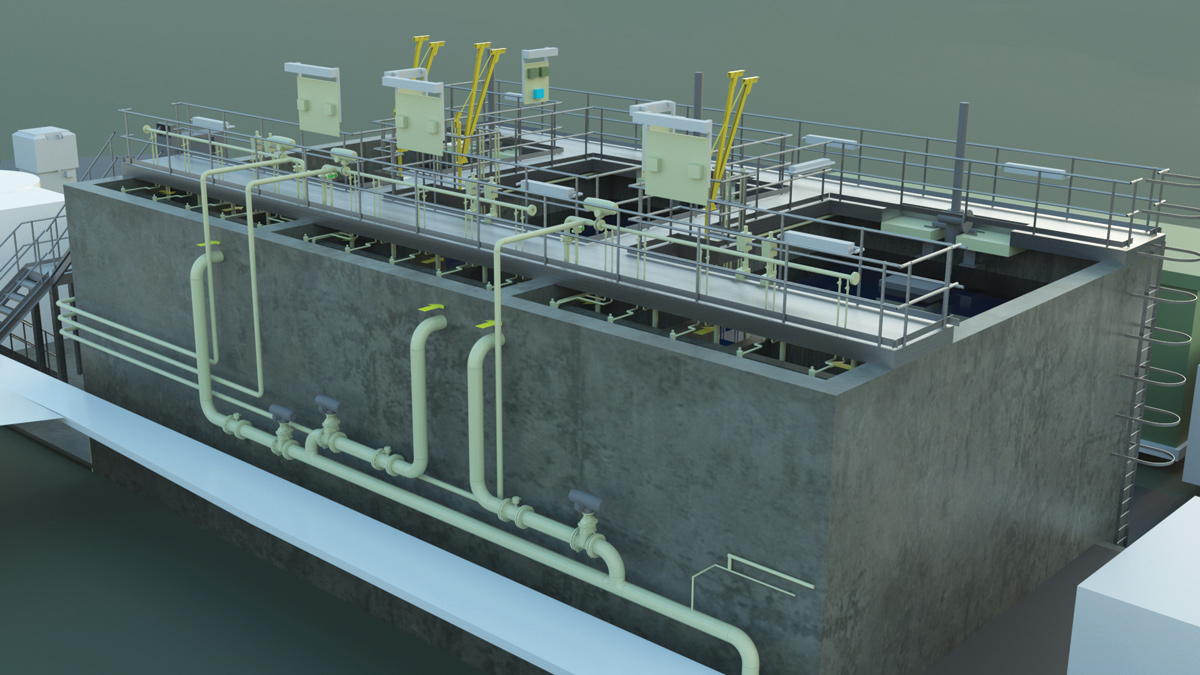

Tony Gee and Partners designed a cofferdam comprising 84 (No.) crimped pairs of AZ46-700N sheet piles which formed the walls of the cofferdam extending 20.6m into predominately loose weathered chalk. In addition to the cofferdam – two sections of deflector piles – sheet piled walls have been installed to assist in diverting the river flows and reduce the loading on the temporary cofferdam. The flagship cofferdam design is allowing a safe environment for around 40 employees working on this project daily.

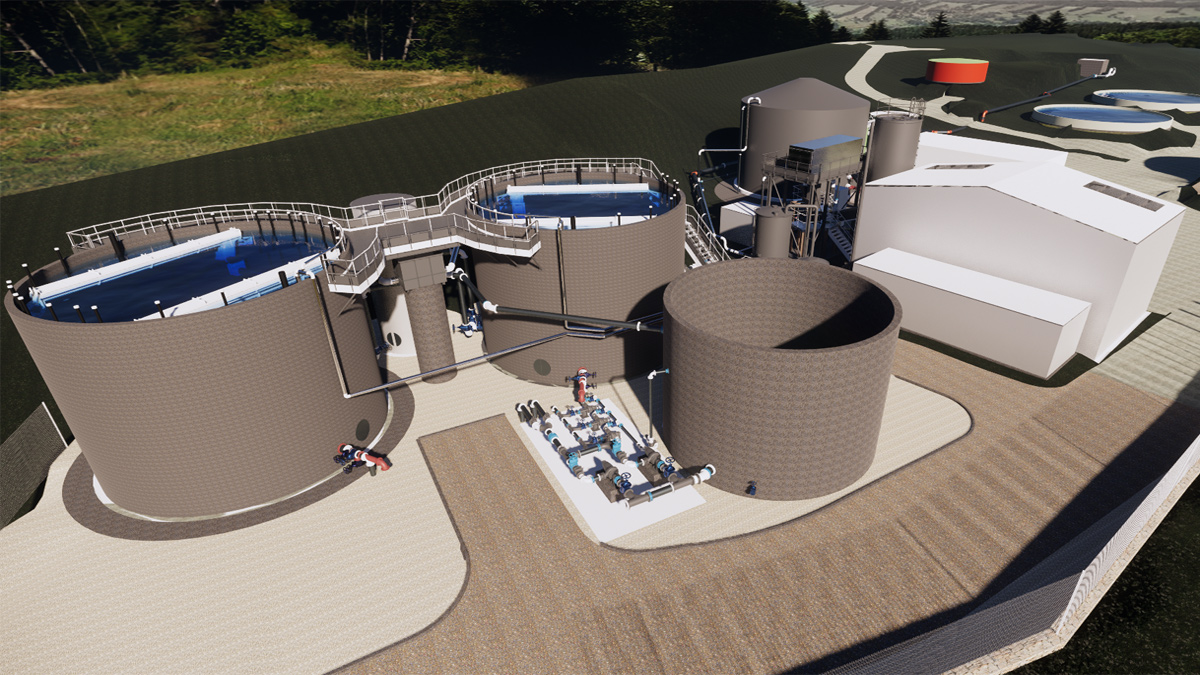

The gate itself is a hollow steel structure with radial arms pivoting at each end, designed by IRS, a German specialist firm, and was manufactured in the Netherlands by Hollandia. It will be floated across the North Sea in October 2017, fully assembled, and placed into the concrete civils structure across the River Orwell. The gate will operate in a similar way to the Thames Barrier and will rise during periods of extreme high tides. This will hold back the North Sea, protecting 2,000 homes and businesses from the devastating effects of floods.

Steve Hesketh, Director, MGF Ltd said:

“Our design team enjoy taking on extremely complex projects, and this was certainly one of our most challenging to date. Only by working closely with the permanent works design team and the contractor were we able to develop a practical and cost-effective solution to an extremely complicated problem. Our detailed design and bespoke manufacturing agility allowed the solution to evolve in response to the site issues encountered.”