MGF Ltd

Installation of New Foul Pumping Station in Jersey

MGF Ltd

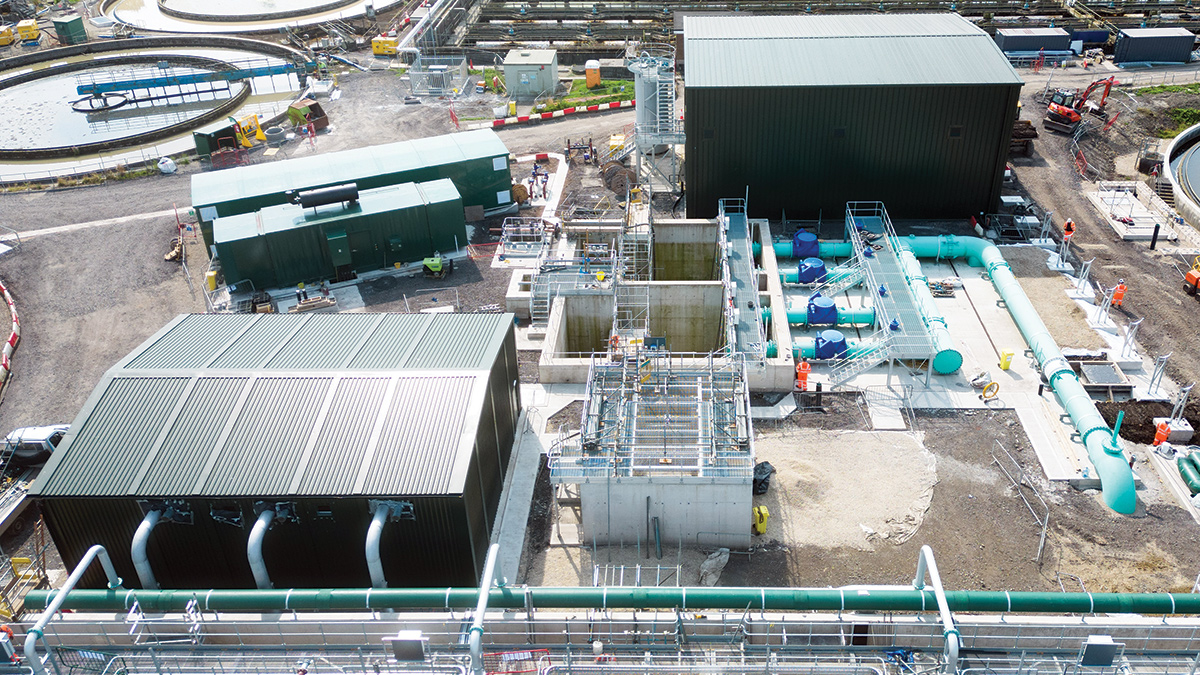

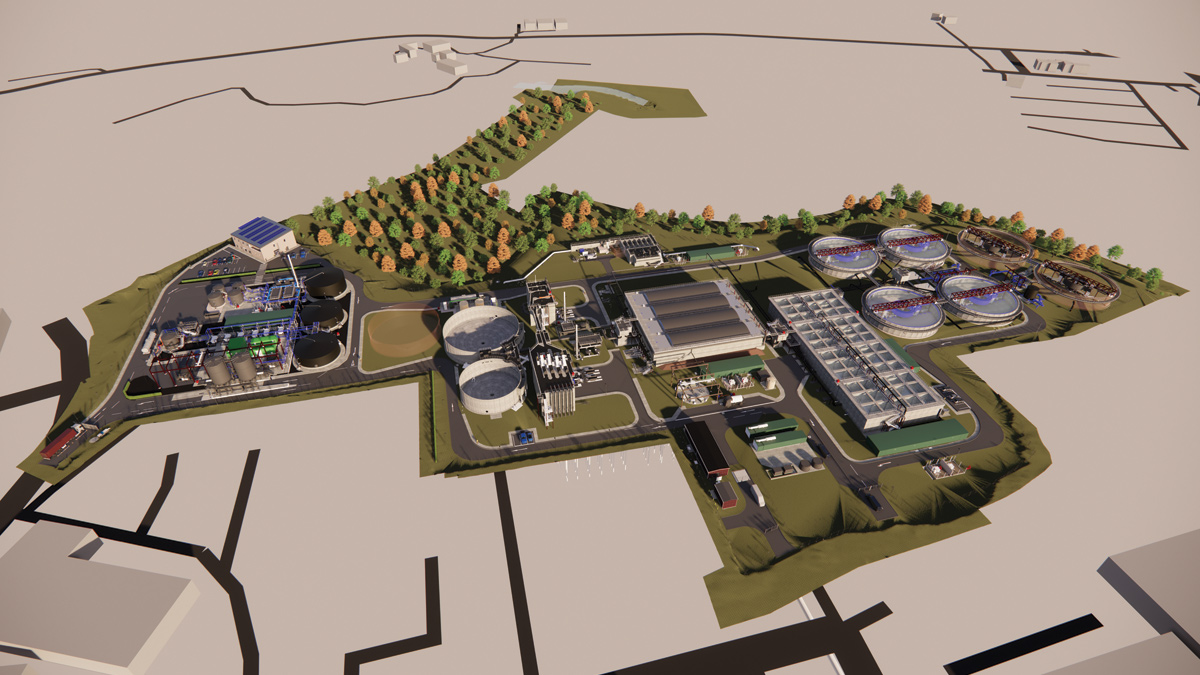

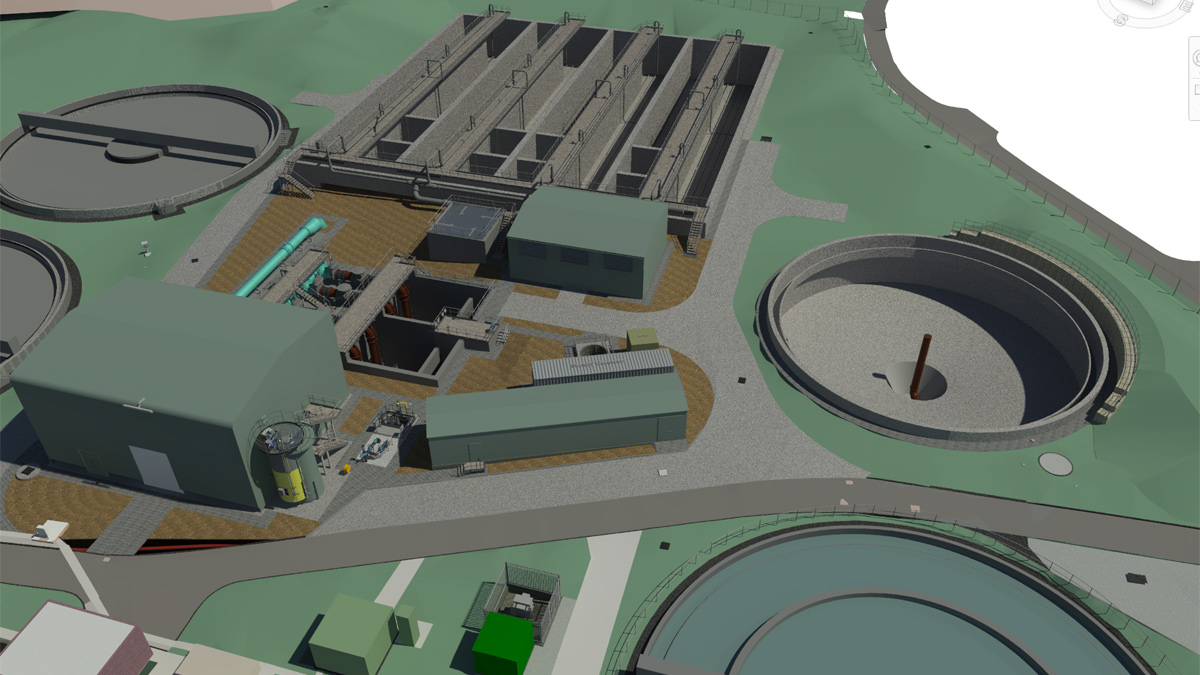

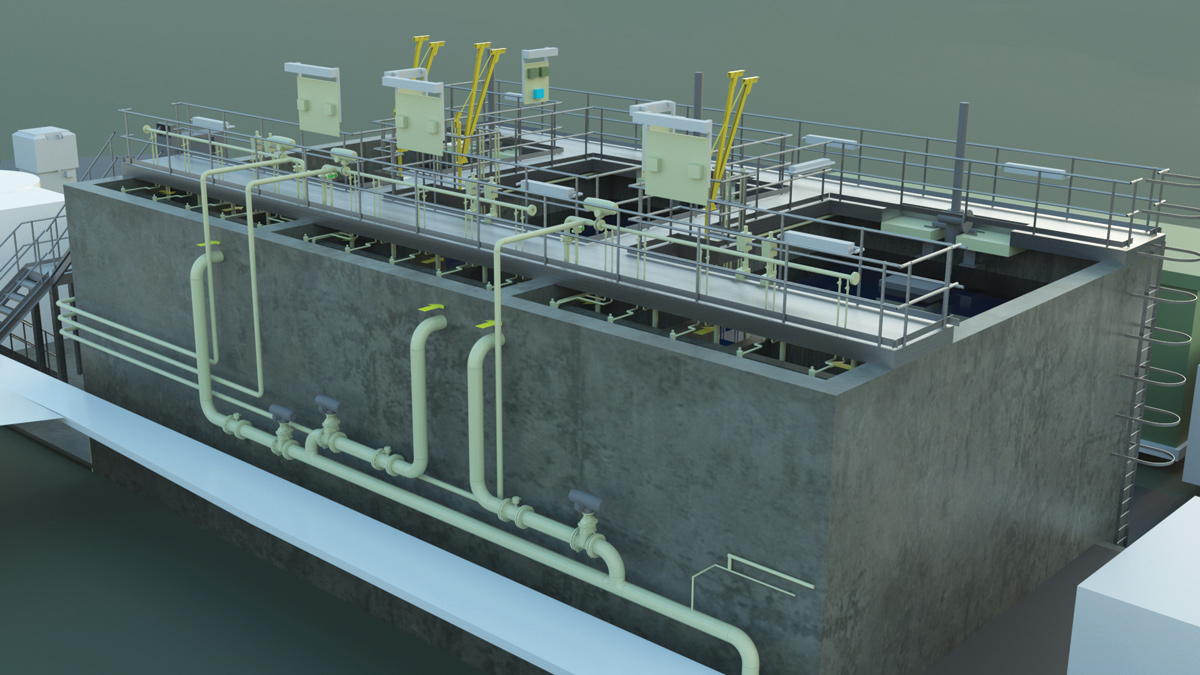

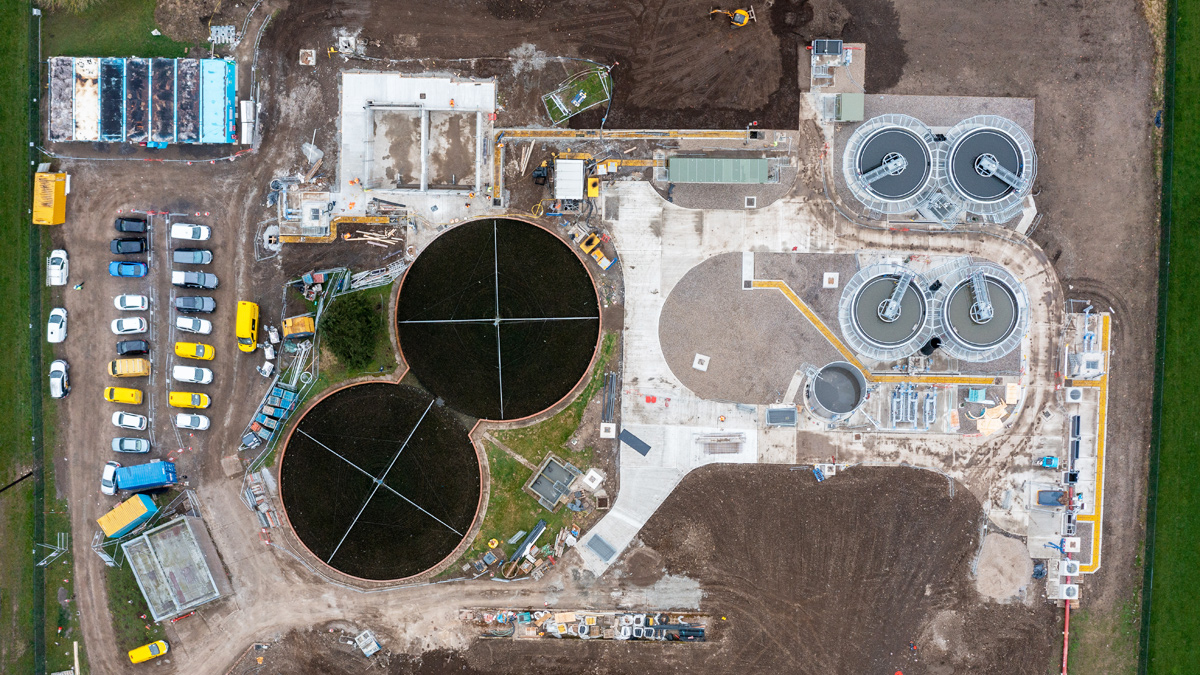

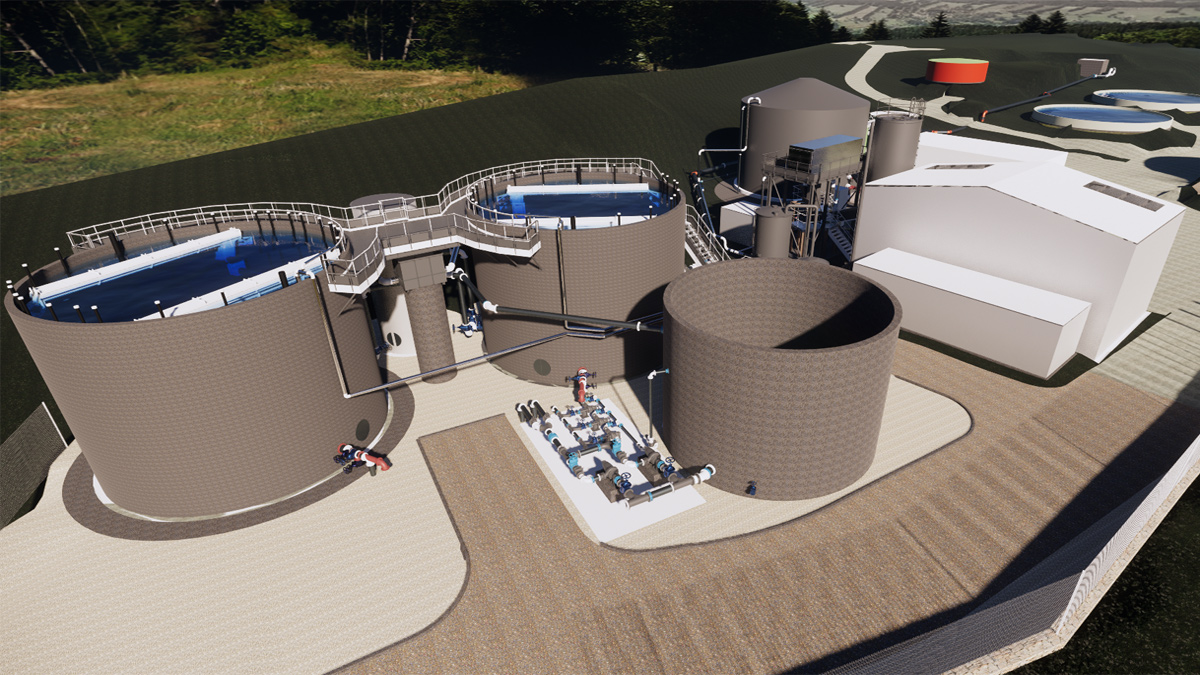

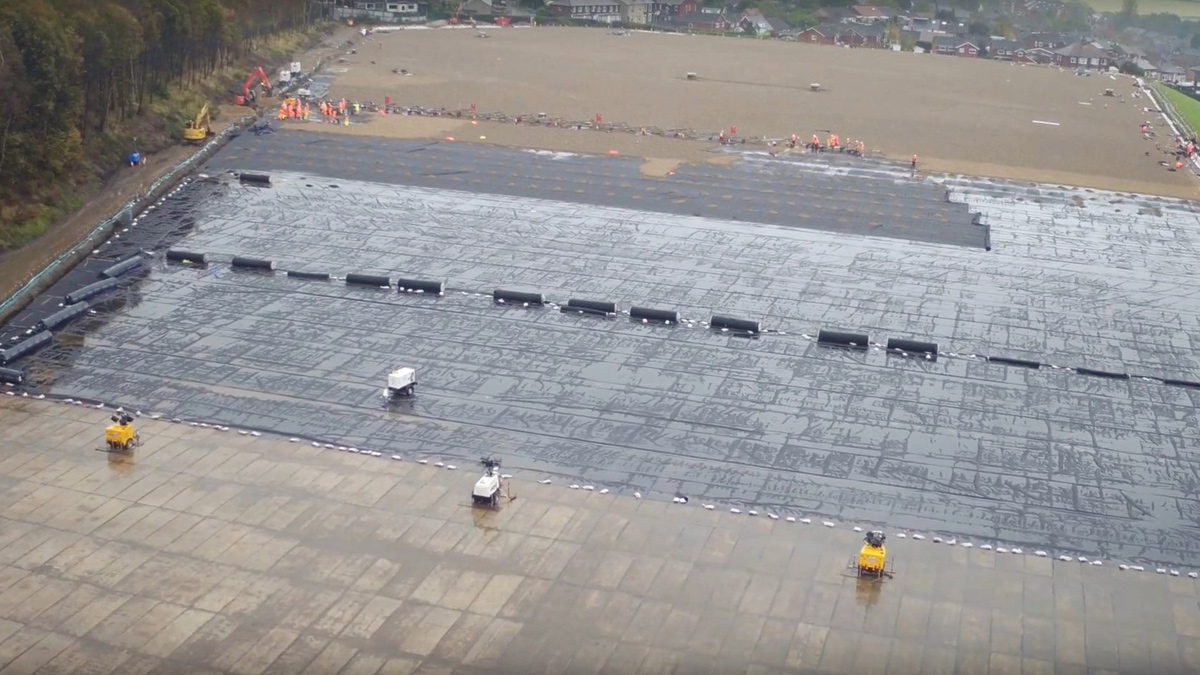

A support system was required for the installation of a new foul pumping chamber tank and customers D.B Cummins (Jersey) Ltd called for MGF’s assistance to meet a tight construction programme. The report from the sub-contractor, D.B.Cummins Ltd, detailed a 15m x 12m x 3m deep excavation with groundwater at 2m, with poor clay conditions throughout – requiring engineering designs and advice on the most efficient and safe support system.

Project details

- Sector: Exports

- Contractor: DB Cummins (Ltd)

- MGF Depot: South East – Tring

- Product hired: 254UC, 203UC with cross struts

Managing Director, Pierce Cummins, praised MGF’s efforts here noting:

“… the technical design and information was very helpful to present to our client. I couldn’t have asked for better customer service. Chris and his team looked after us from initial design all the way through to shipping equipment back to the UK.”

Chris Whitworth, MGF’s International Sales Manager added:

“… it was important to Pierce to ensure that we met their construction programme. The design was completed and approved by their external consultant and equipment was on site, on time, as assured.”

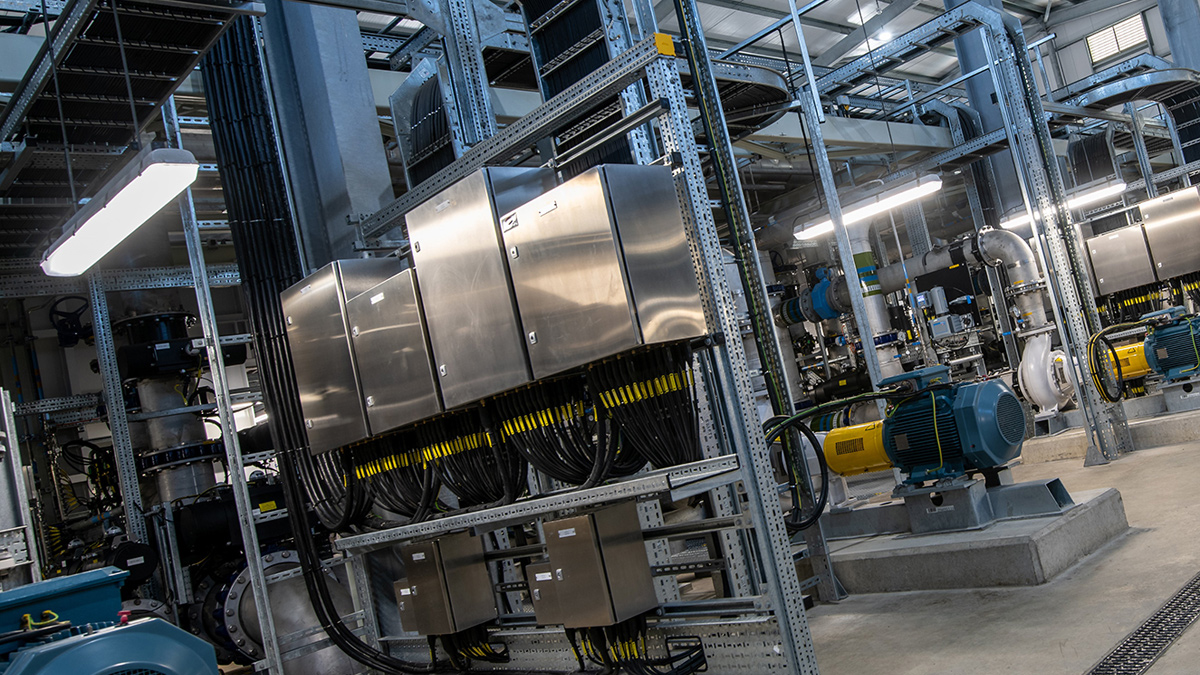

Equipment was pre-assembled at MGF’s Tring Depot – including 254UC, 203UC braces complete with a 60T cross strut – and delivered to Southampton docks for shipping direct to site.

For more information: MGF Ltd | +44 (0)1942 402700 | www.mgf.co.uk