MGF Ltd

Bridgwater Water Supply

Bridwater Water Supply temporary works

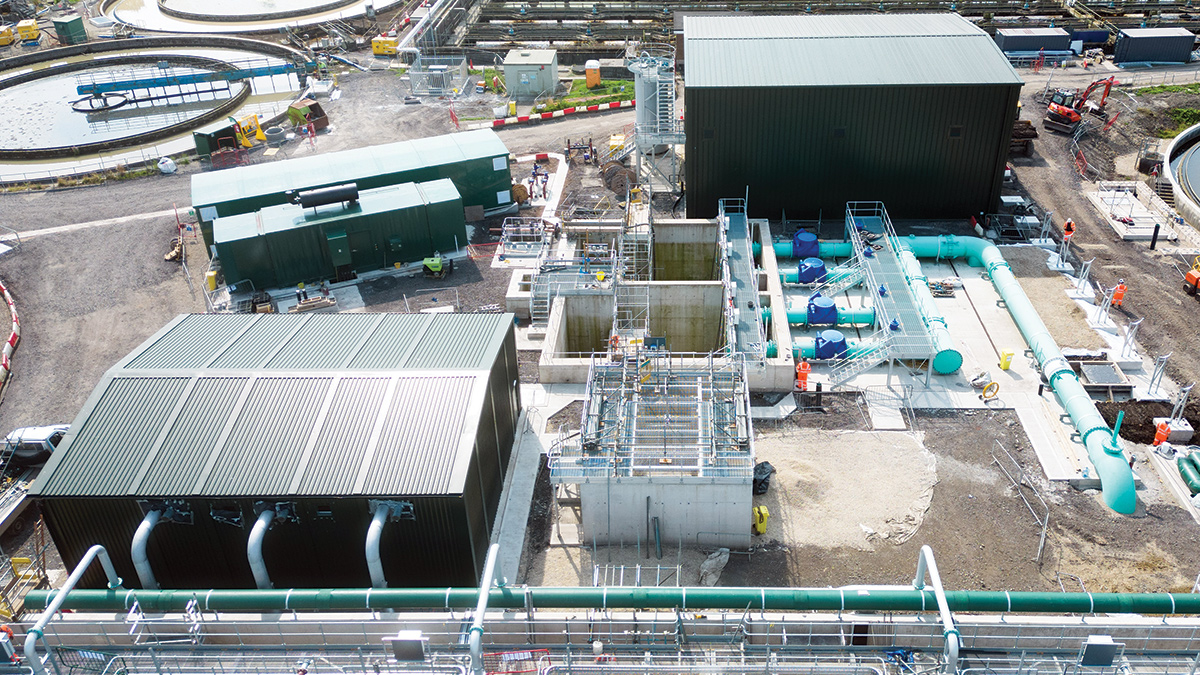

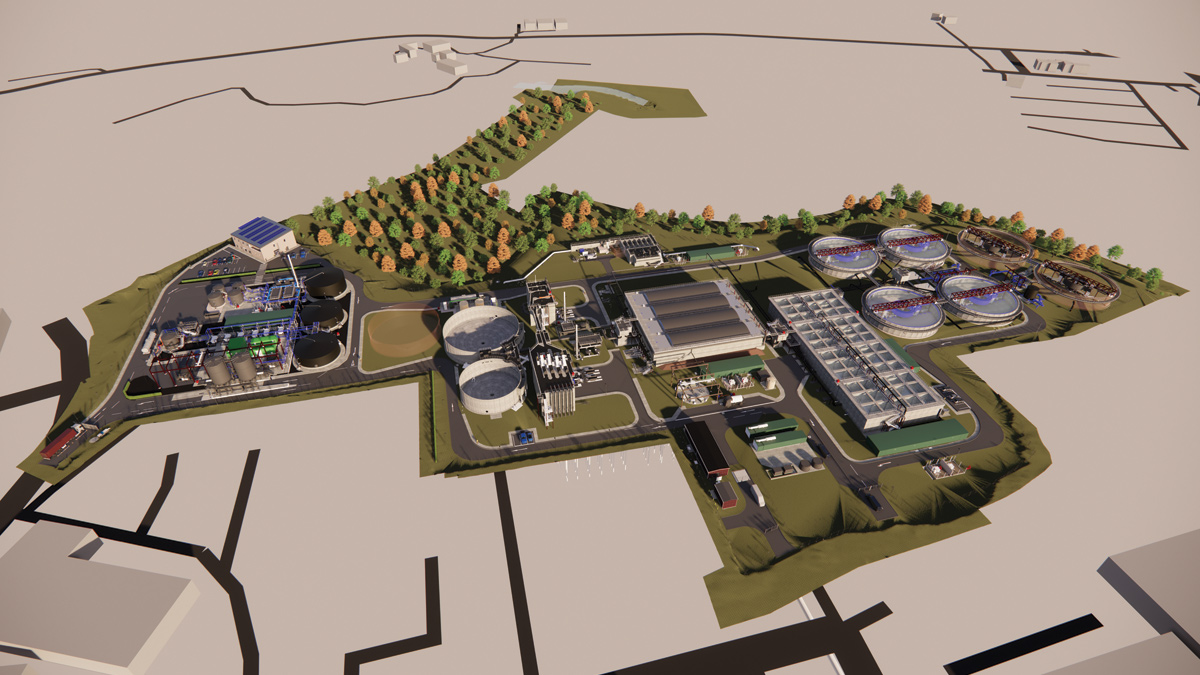

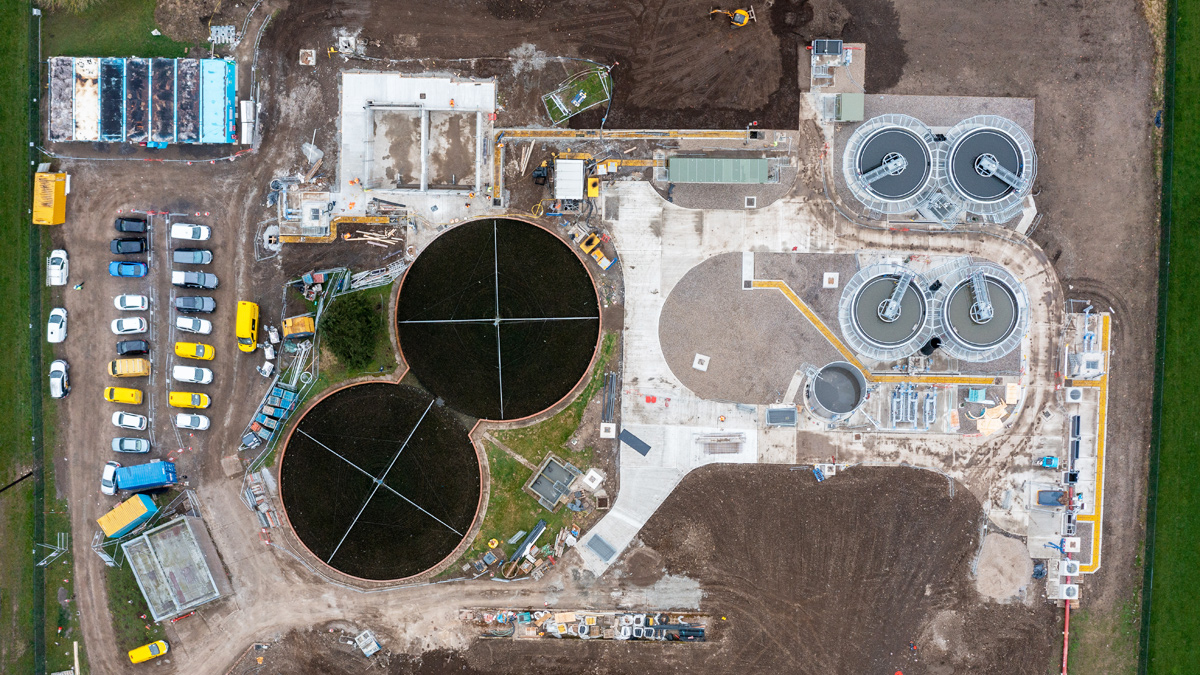

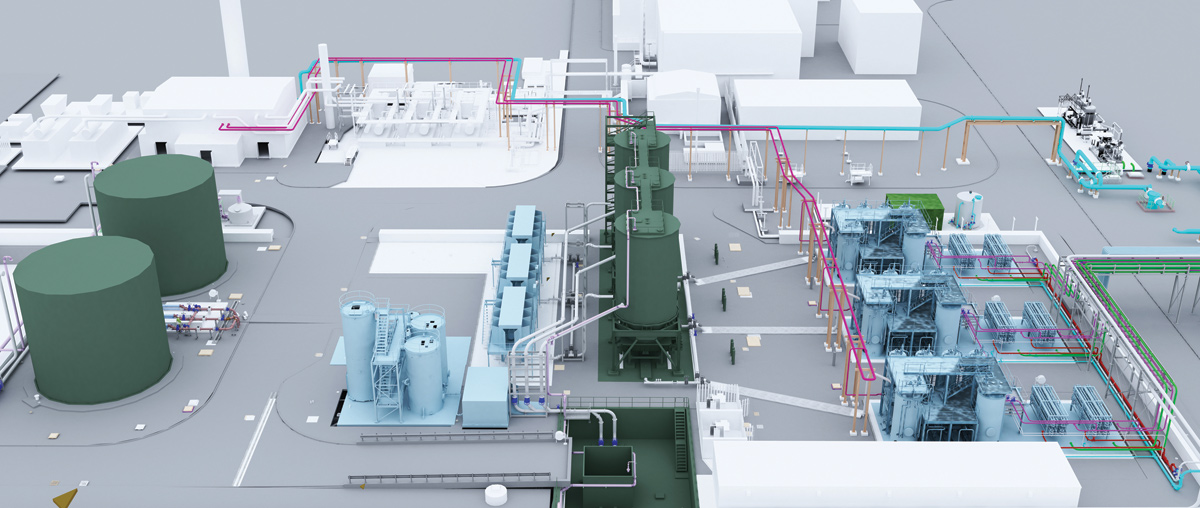

Excavation works began in early 2017 at the Dancing Hill Reservoir site as part of a £6 million project to upgrade the water supply grid for Bridgwater and the surrounding areas. Major upgrades are required due to large-scale developments in the area.

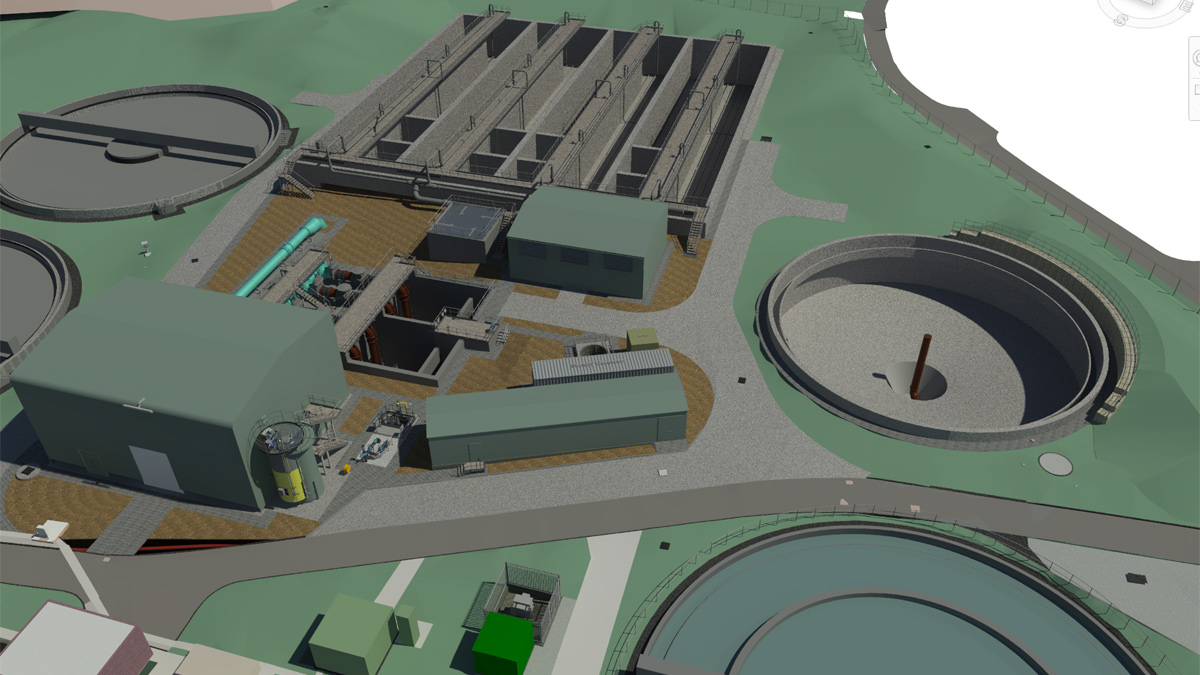

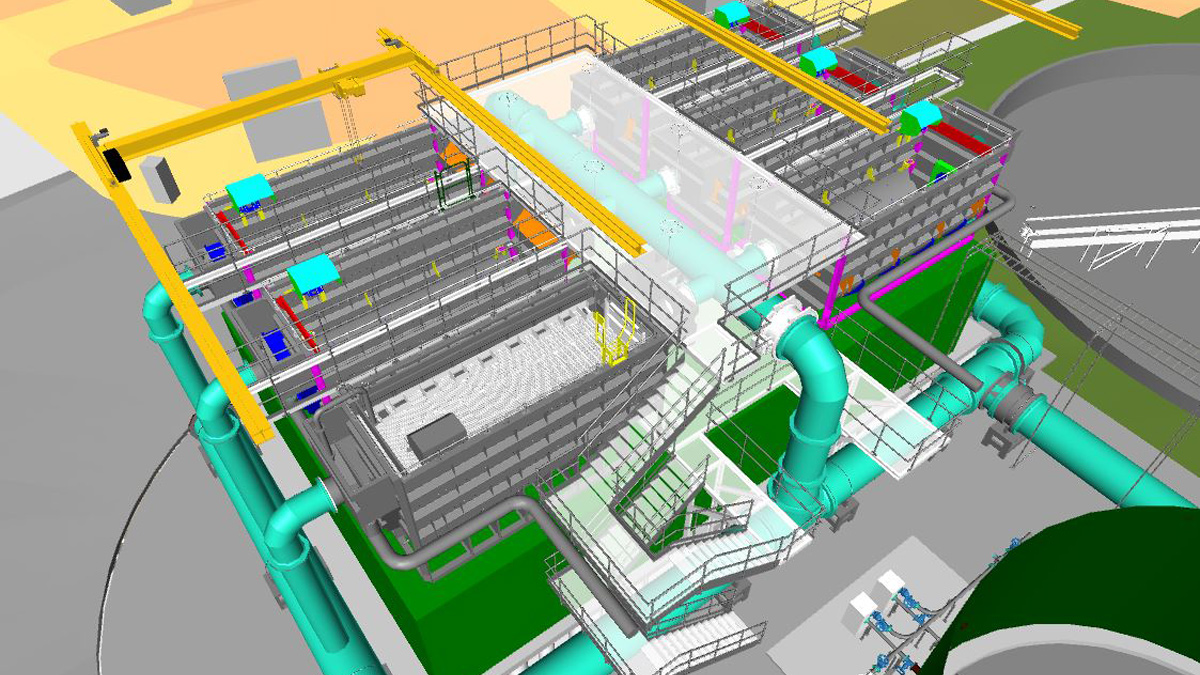

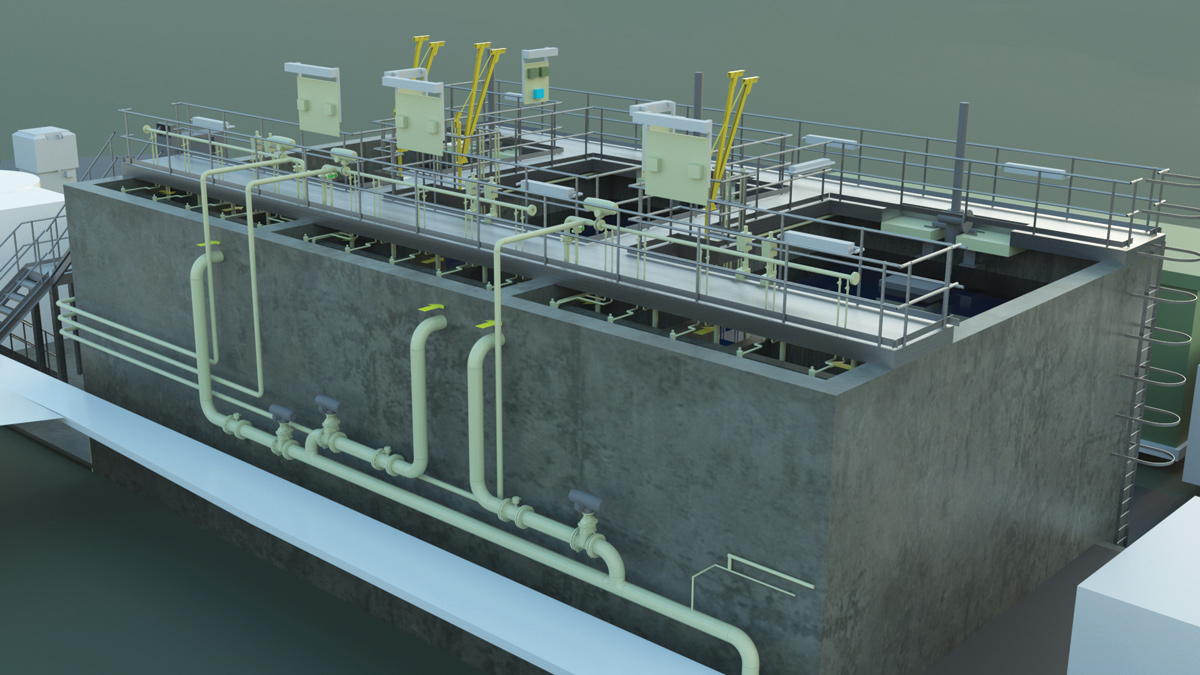

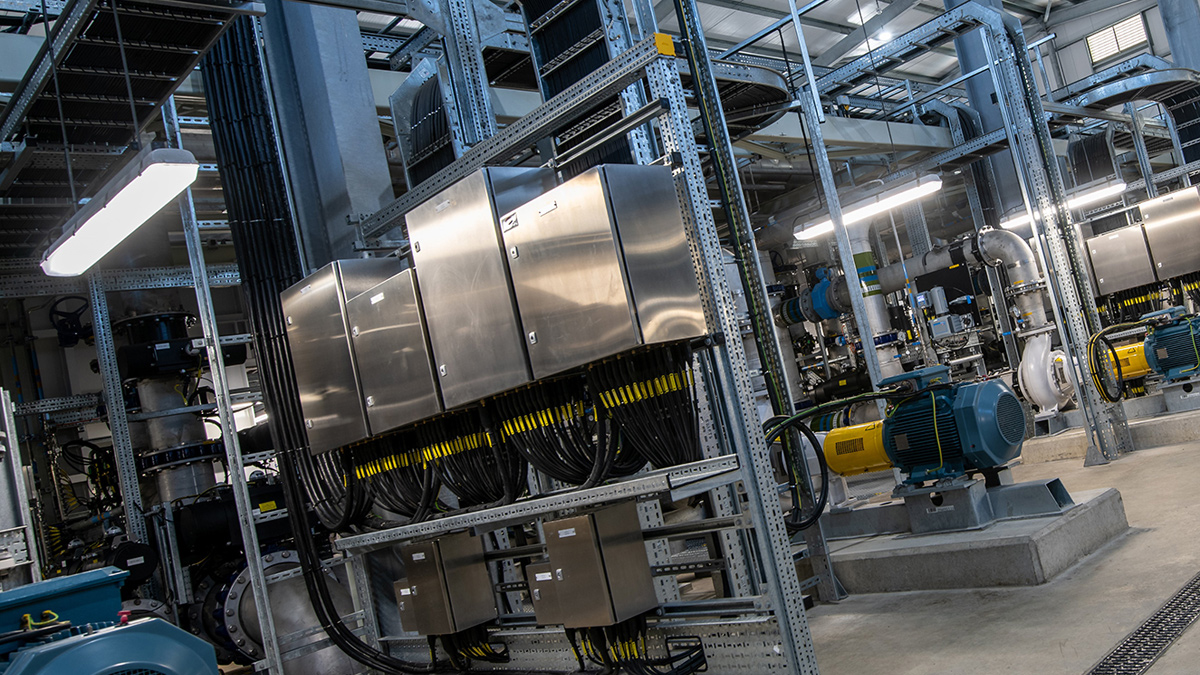

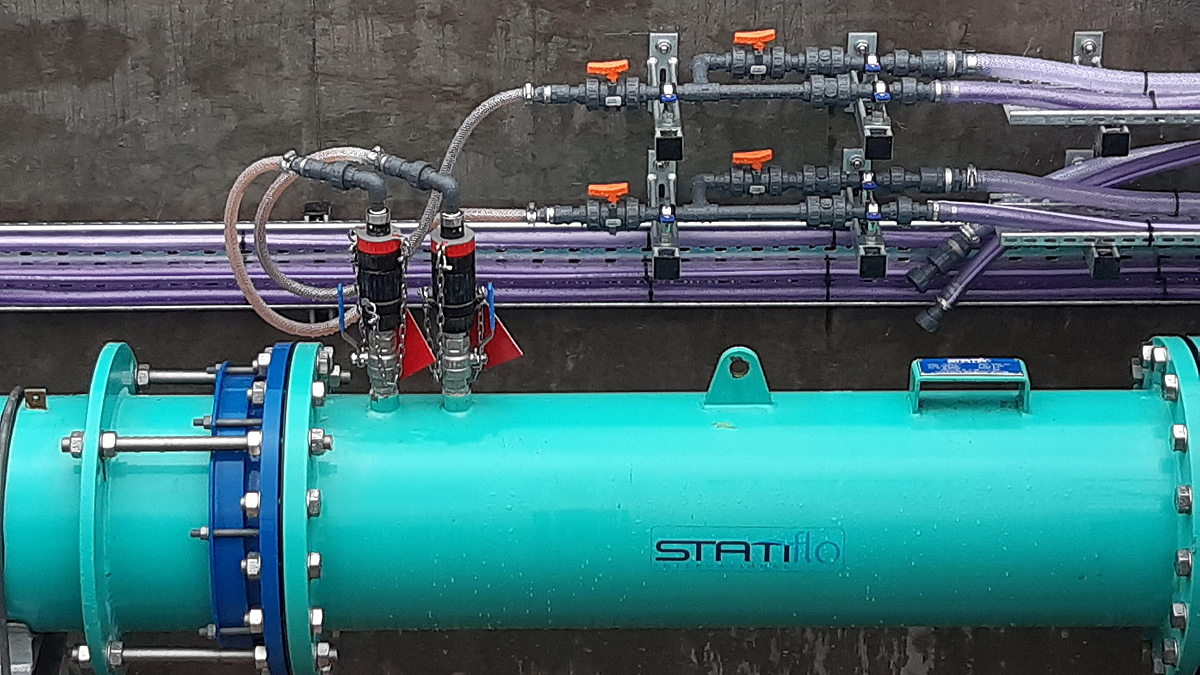

The solution

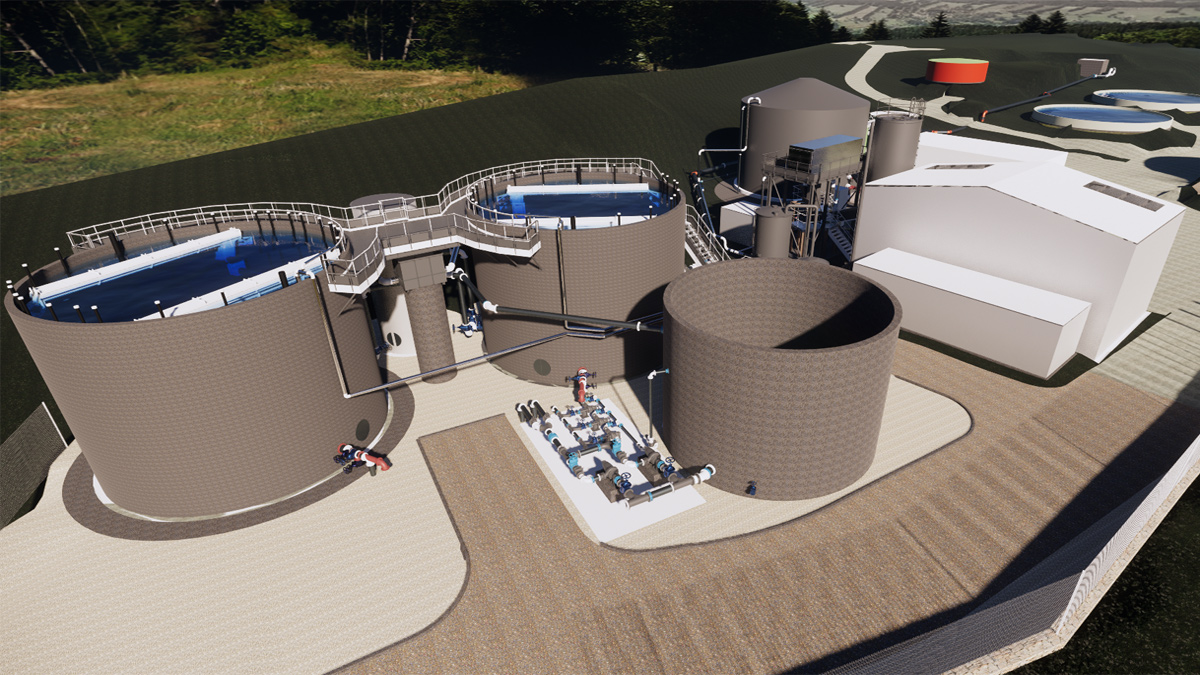

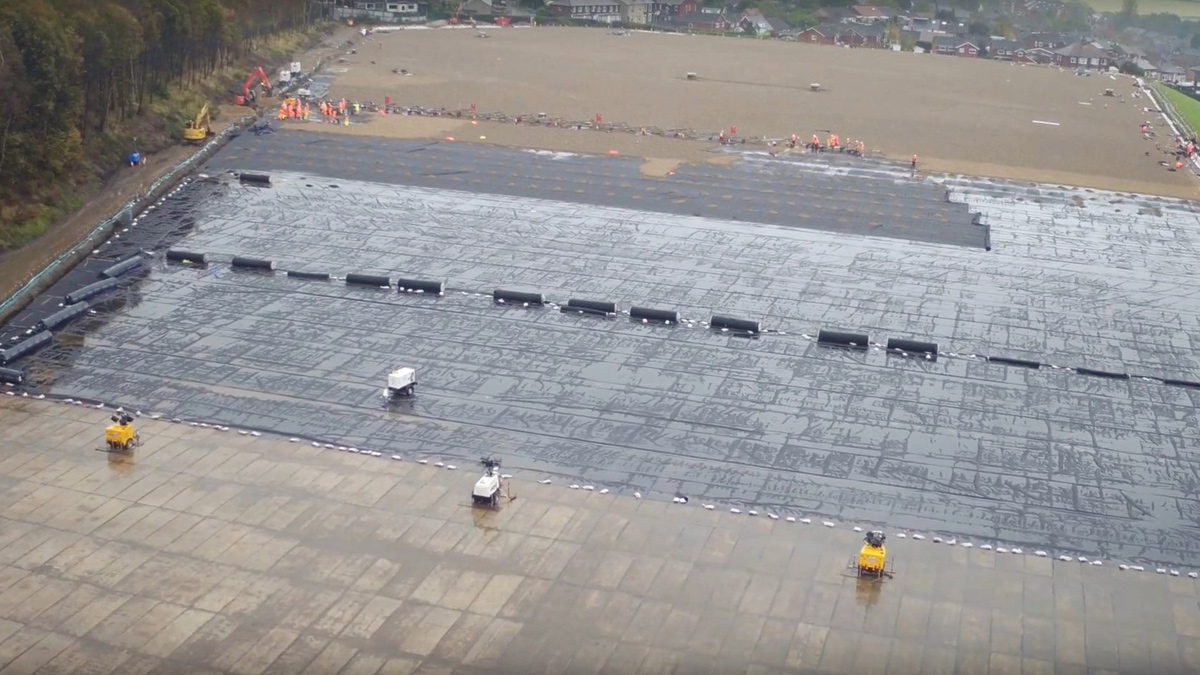

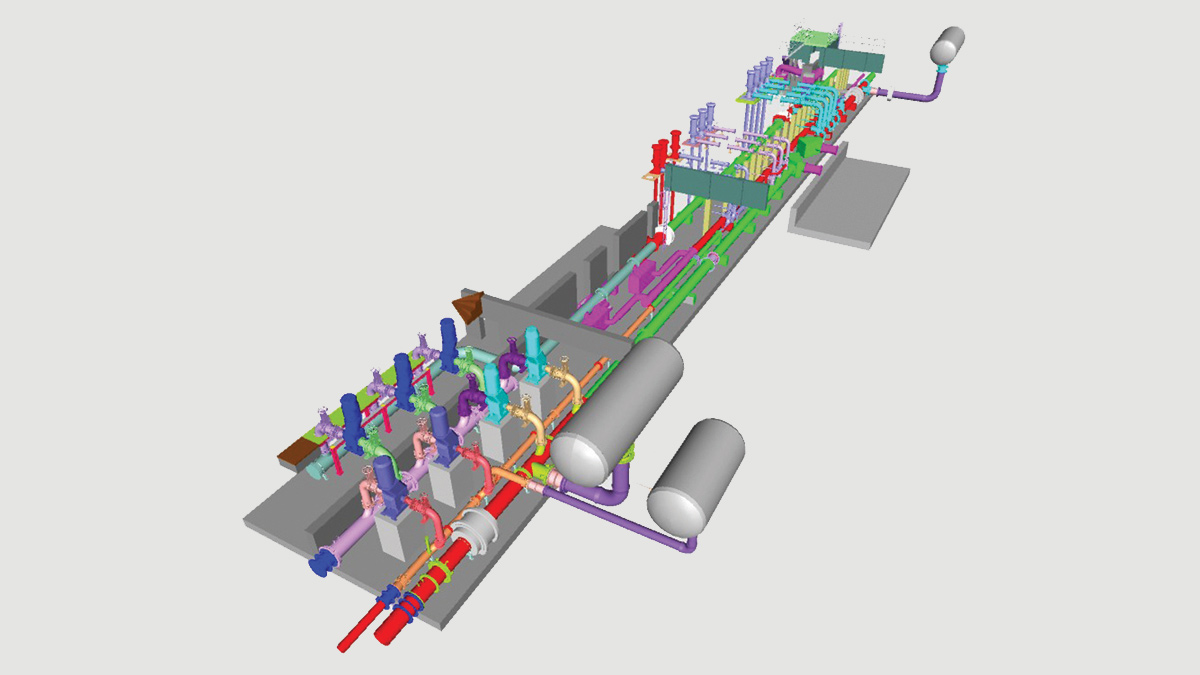

The project has four connected cofferdams in place allowing safe working space to combine new pipeworks to the main reservoir tank. Multiple back-to-back 203UC tank braces with special alignment of bracing has been key in the design, combined with KKD 600 sheets to secure the trench. Several Lightweight DavitSafe systems allow safe access into the 10-metre-deep cofferdams.

The design was particularly challenging due to the complicated nature of the ground surrounding the reservoir tank. A sizeable berm was built on the ground profile around Cofferdam 4 to ensure a safe and stable excavation.

This exaction also had to accept other loadings from Cofferdams 1, 2 and 3. Multiple 203UC tank brace frames were used due to the strict lift plan limit of 1 tonne. Larger or heavier brace systems could risk the collapse of existing foundations.

Vibration pile driving was not permitted due to the detrimental effect it could have on the high-pressure water mains that supplies customers. There was also a HV cable running through the site that had to be avoided. The exact location of other services created additional challenges and ongoing surveys had to be monitored throughout the duration of works.

Paul Chedzoy, Construction Manager, Wessex Water commented:

“Once these works are completed then the new upgraded line will be tested and commissioned and will link up with another reservoir. It will ensure the reservoir will be able to cope with the increased demand that is required in the coming years ahead and allow us to move water around our water supply network.”

For more information: MGF Ltd | +44 (0)1942 402700 | www.mgf.co.uk