MGF Ltd

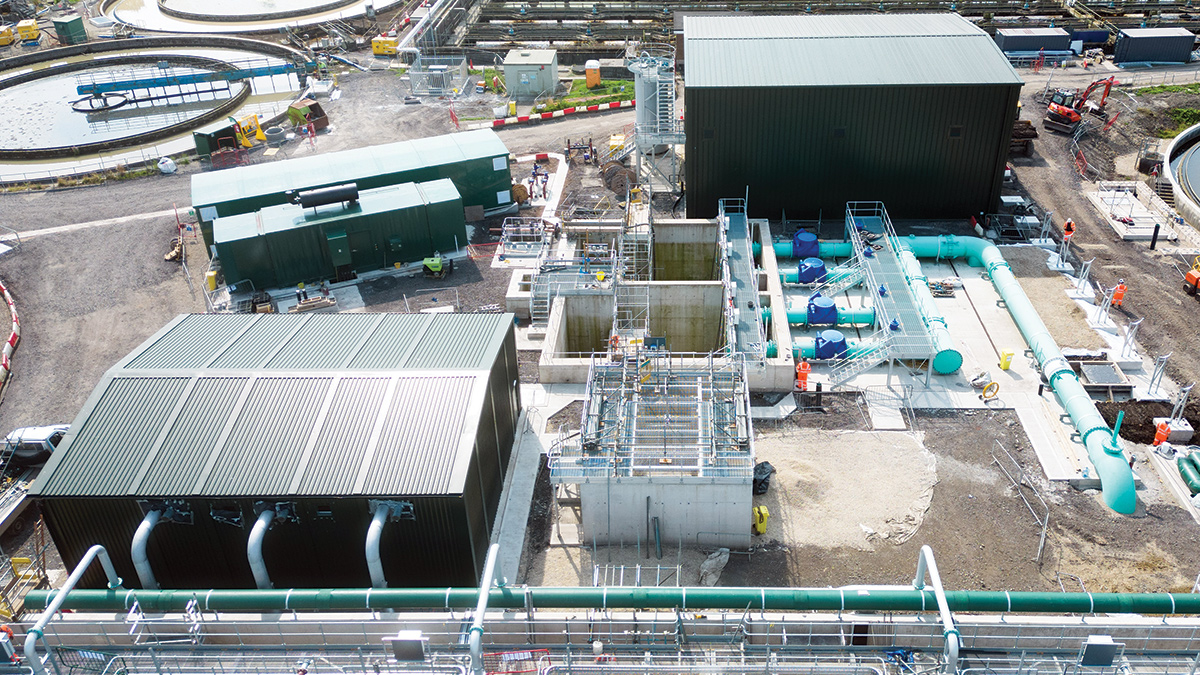

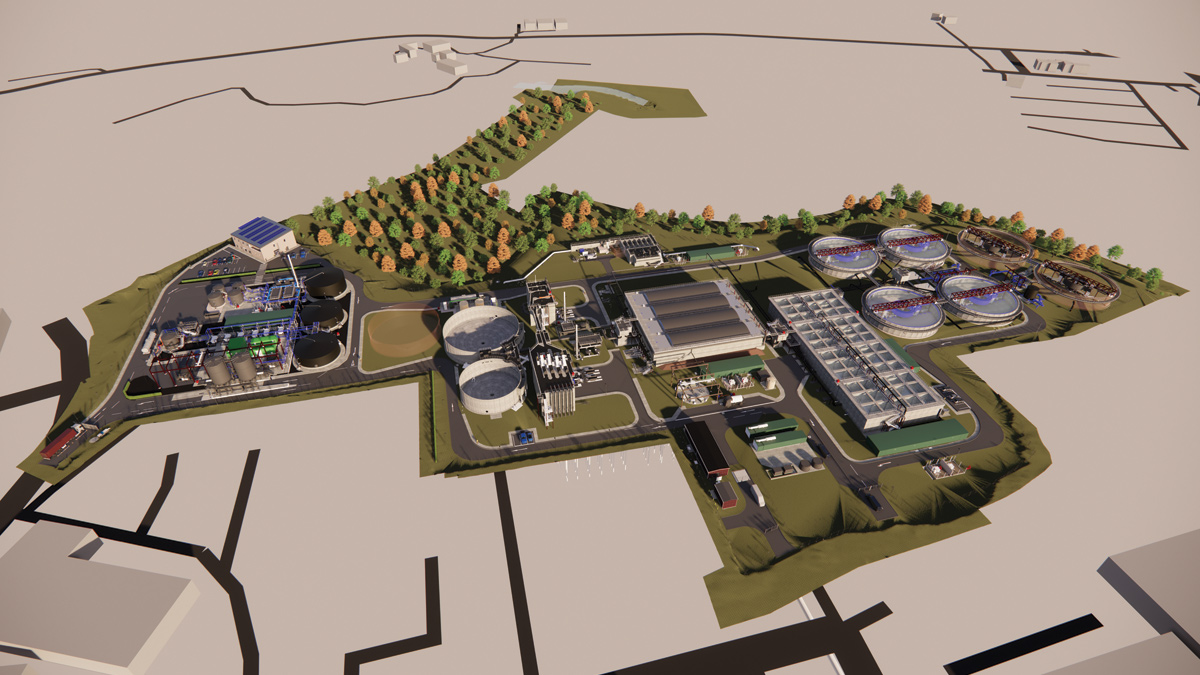

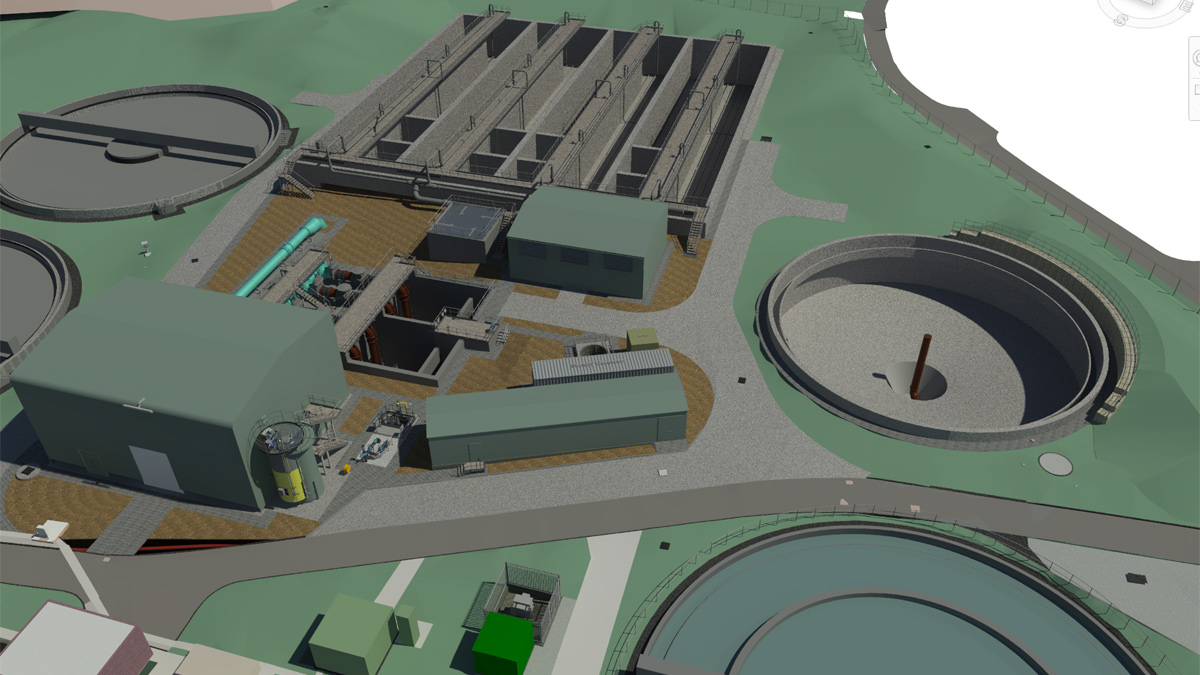

Hornsey WTW

Hornsey WTW lamella building excavation

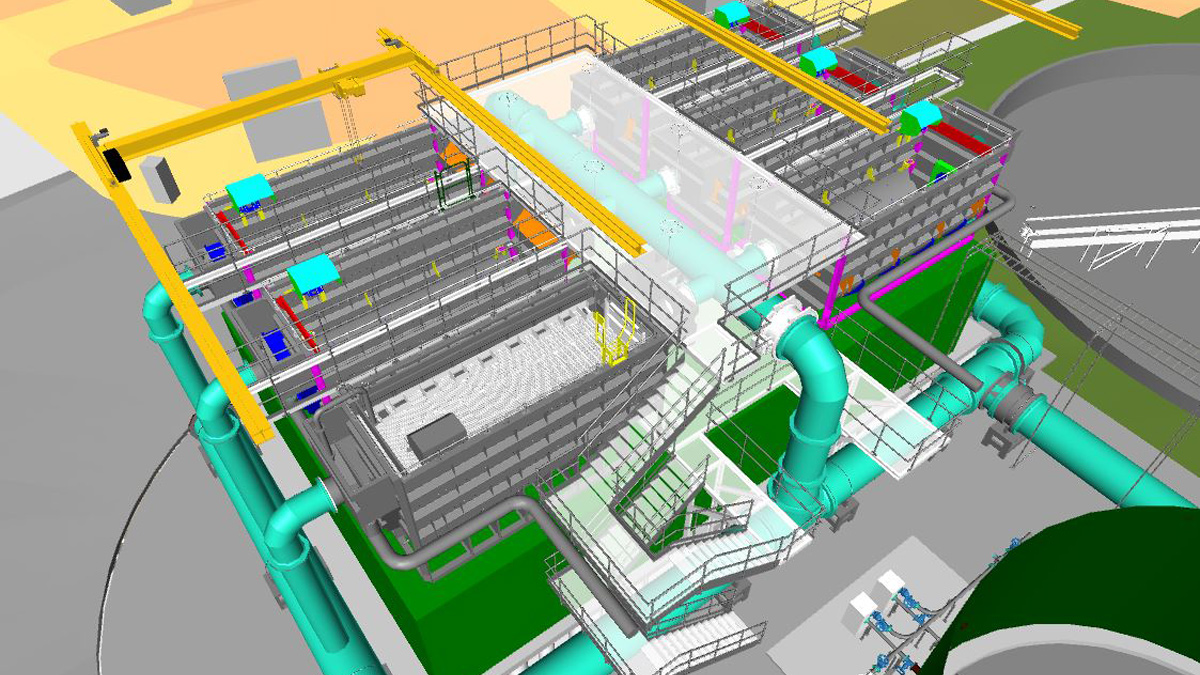

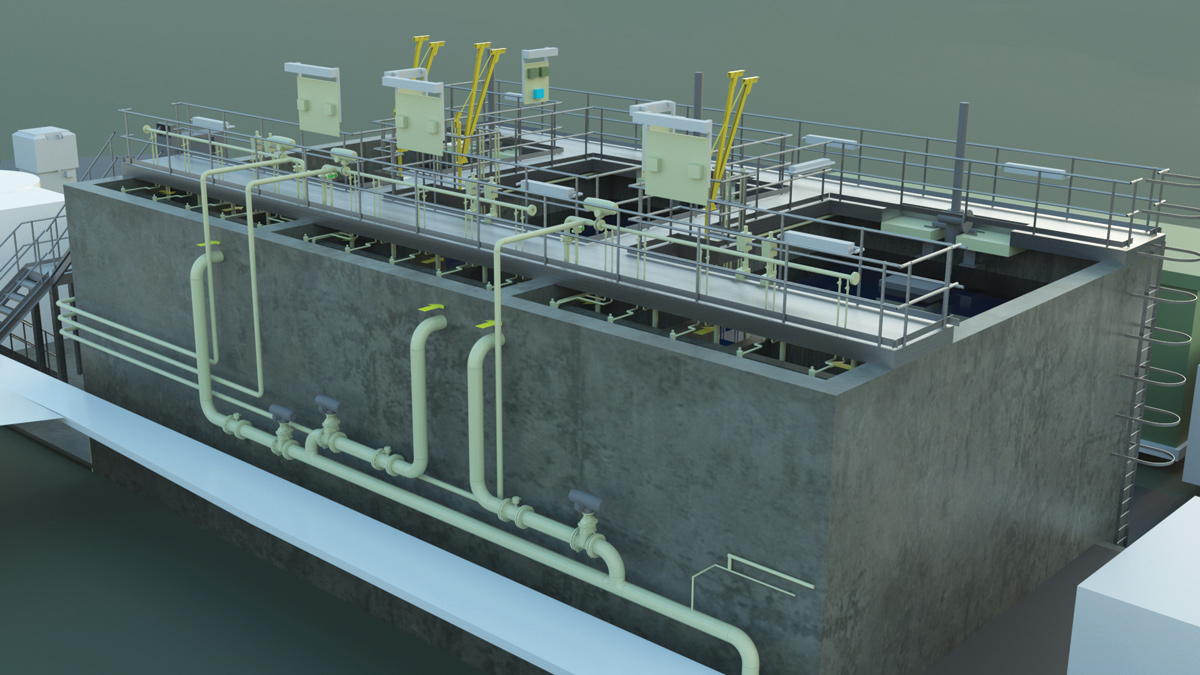

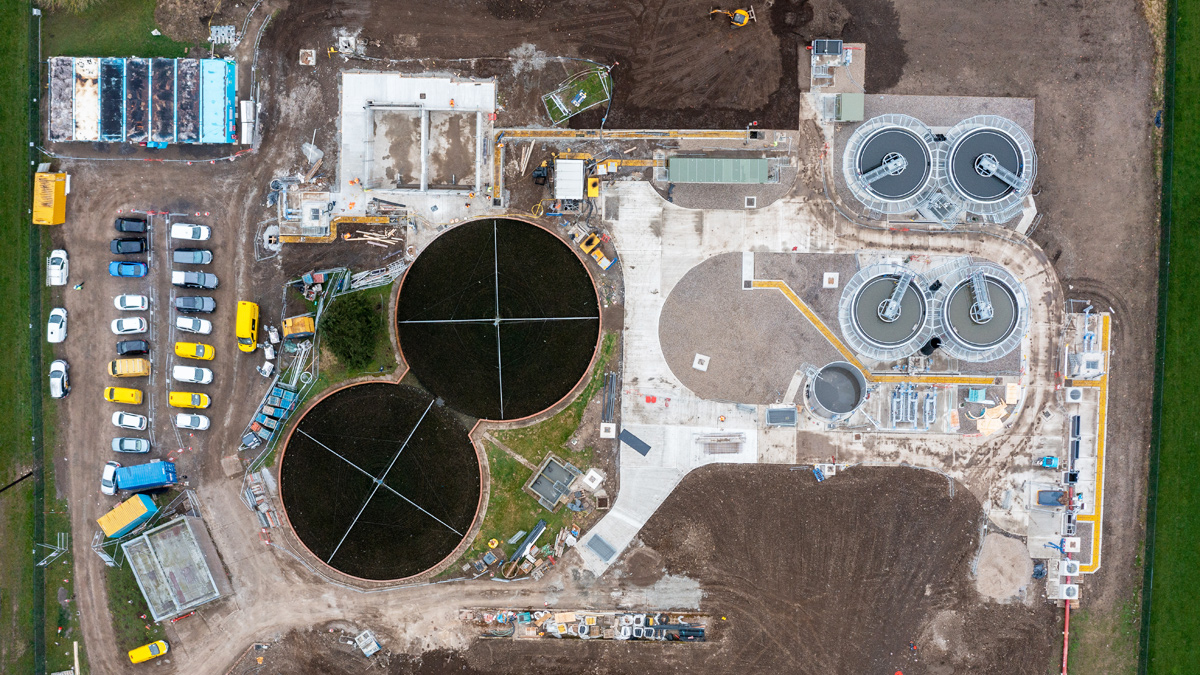

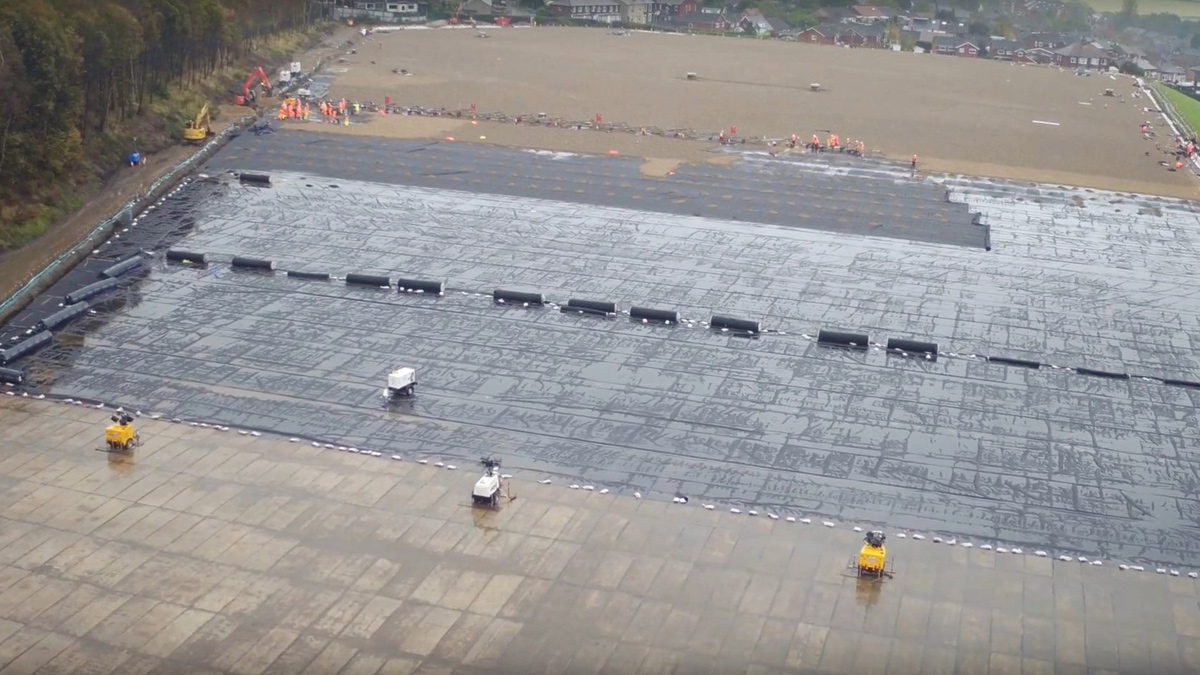

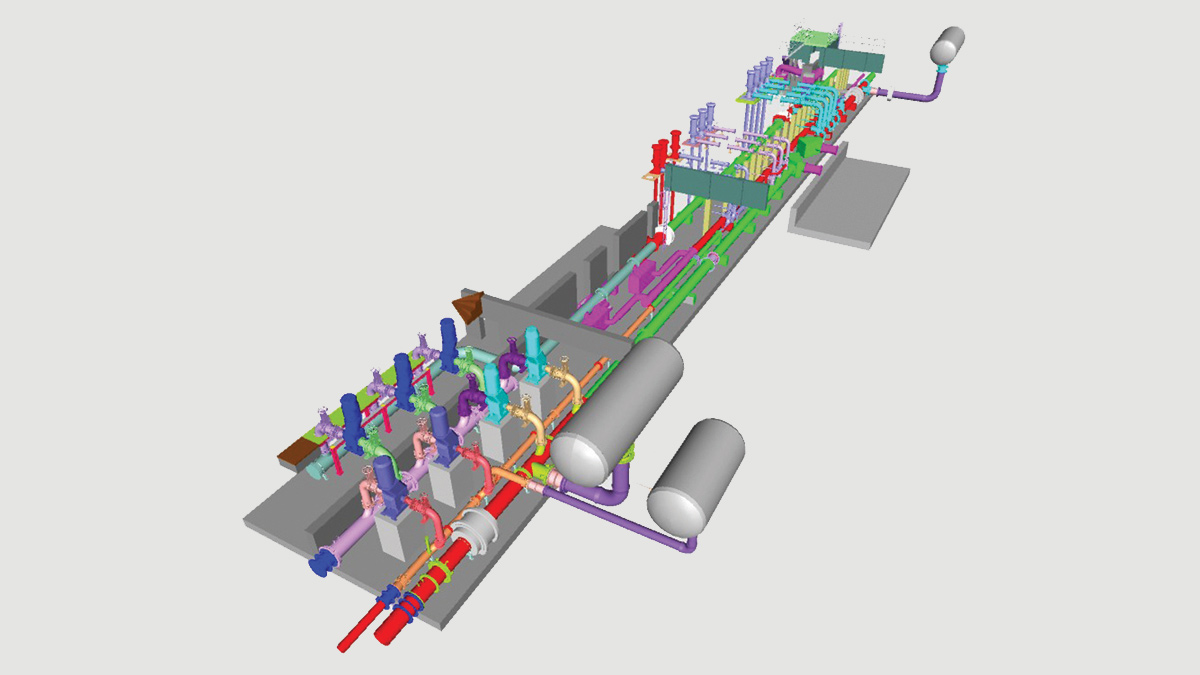

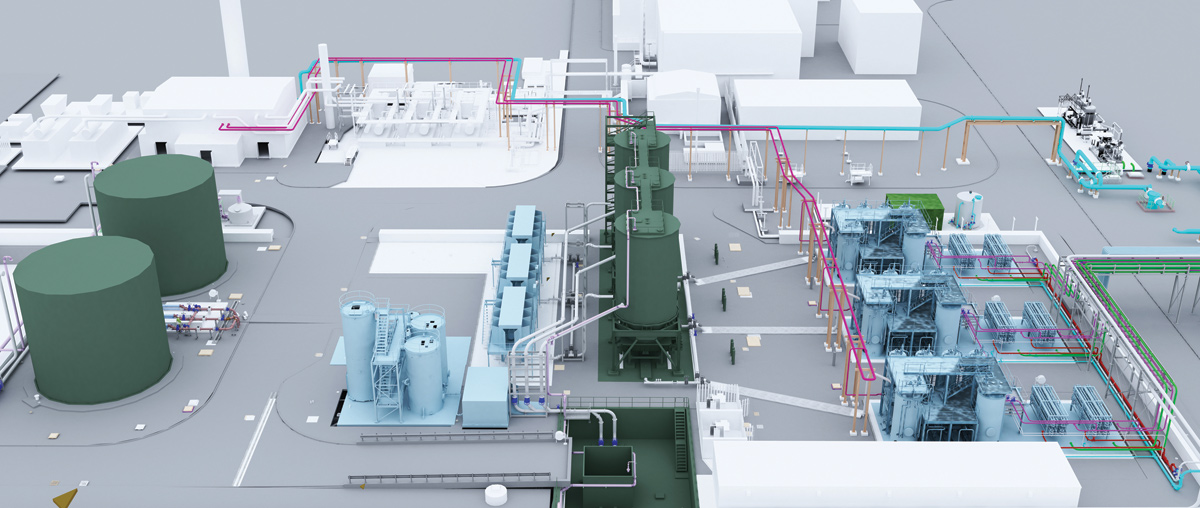

As part of their AMP4 programme Costain asked MGF to design and supply numerous temporary works solutions for seven schemes on a large WTW improvement scheme. The largest and perhaps most challenging schemes on the site was the Lamella Building excavation. The 7.4m deep excavation measured 58.3m x 17.4m and was adjacent to a river and reservoir, therefore is was essential that ground movement was kept to a minimum and had to be monitored continuously throughout the works.

The solution

MGF provided a solution comprising two frames of MGF 406UC Brace complete with MGF 1200kN and 2500kN Hydraulic Struts, combined with MGF 400 Series Strut Extensions configured as cross struts and knee braces to support a sheet piled wall cofferdam. Additional struts were required in the lower frame where a greater depth was required locally.

The verdict

Through careful co-ordination with Costain Engineering Services, Thames Water and the piling subcontractors throughout the project, MGF’s excavation support system successfully managed ground movement during the works. Hornsey represented the largest single site supply of equipment for MGF in 2007.

For more information: MGF Ltd | +44 (0)1942 402700 | www.mgf.co.uk